10 Best Air Filtration For Laser Engraver 2025 in the United States

Winner

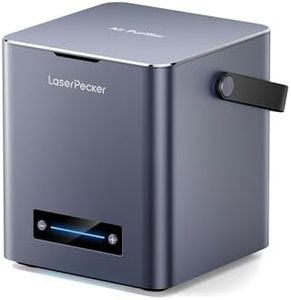

LaserPecker Air Purifier & Fume Extractor for Laser Engraving, 99.97% Filtration, 55dB Quiet, 4-Layer HEPA Filter, Portable Smoke Cleaner for LP2/LP3/LP4/LP5 Machines & Cubic Protective Cover

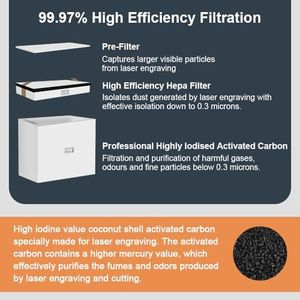

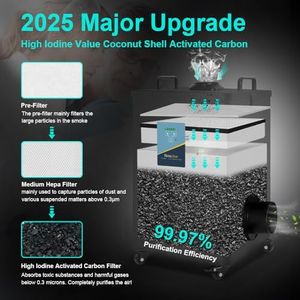

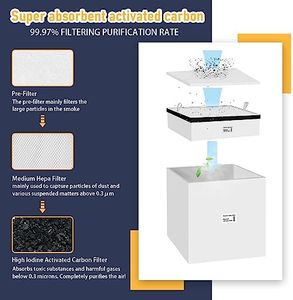

The LaserPecker Desktop Smoke Air Purifier is designed to efficiently filter smoke and fumes generated during laser engraving on wood and metal. It boasts a high filtration efficiency with its 4-layer system, which includes activated carbon and HEPA filters capable of capturing particles as small as 0.3 microns with an impressive 99.97% efficiency. This ensures that your workspace remains clean and healthy. The purifier is relatively quiet at a noise level of 55 dB, making it suitable for use in quieter environments without causing much disturbance.

Most important from

5 reviews

xTool SafetyPro AP2 Smoke Purifier for Laser Engraver, SuperCyclone System 6-Layer Filtration for Dust & Odors, Quiet Operation for Diode Fiber Laser Engraving Machine and CO2 Laser Cutter

The xTool SafetyPro AP2 is designed to keep the air clean while using laser engravers, capturing 99.99% of dust and odors with its advanced 6-layer filtration system. Its standout feature is the SuperCyclone Technology that uses 36 cyclones to remove large particles before the filters, which helps extend filter life by up to 10 times compared to typical purifiers. This means less frequent filter changes and lower maintenance costs. The purifier works well with xTool laser machines and other laser or hybrid 3D printers, making it versatile for different setups.

Most important from

35 reviews

KQZ [Specialized] 210W Laser Fume Extractor 330m³/h Strong Suction for S1/F1/ M1/LU3 Most Laser Engraver, Solder Fume Extractor with Exhaust, Odor Smoke Purifier for Lasering Soldering 3D Printing

The KQZ 210W Laser Fume Extractor is designed specifically for laser engraving and similar applications, making it a great choice for users in crafting, 3D printing, and welding. One of its standout strengths is its impressive filtration efficiency, with a three-layer system that captures smoke particles as small as 0.03µm and offers a 99.97% filtration rate, ensuring a healthier workspace by removing harmful fumes and odors effectively.

Most important from

15 reviews

Top 10 Best Air Filtration For Laser Engraver 2025 in the United States

Winner

10.0 score

LaserPecker Air Purifier & Fume Extractor for Laser Engraving, 99.97% Filtration, 55dB Quiet, 4-Layer HEPA Filter, Portable Smoke Cleaner for LP2/LP3/LP4/LP5 Machines & Cubic Protective Cover

LaserPecker Air Purifier & Fume Extractor for Laser Engraving, 99.97% Filtration, 55dB Quiet, 4-Layer HEPA Filter, Portable Smoke Cleaner for LP2/LP3/LP4/LP5 Machines & Cubic Protective Cover

Chosen by 1241 this week

xTool SafetyPro AP2 Smoke Purifier for Laser Engraver, SuperCyclone System 6-Layer Filtration for Dust & Odors, Quiet Operation for Diode Fiber Laser Engraving Machine and CO2 Laser Cutter

xTool SafetyPro AP2 Smoke Purifier for Laser Engraver, SuperCyclone System 6-Layer Filtration for Dust & Odors, Quiet Operation for Diode Fiber Laser Engraving Machine and CO2 Laser Cutter

KQZ [Specialized] 210W Laser Fume Extractor 330m³/h Strong Suction for S1/F1/ M1/LU3 Most Laser Engraver, Solder Fume Extractor with Exhaust, Odor Smoke Purifier for Lasering Soldering 3D Printing

KQZ [Specialized] 210W Laser Fume Extractor 330m³/h Strong Suction for S1/F1/ M1/LU3 Most Laser Engraver, Solder Fume Extractor with Exhaust, Odor Smoke Purifier for Lasering Soldering 3D Printing

FumeClear FC-2002A Laser Fume Extractor for S1, D1 Pro 10W to 20W Laser Engraver, 260m³/h Strong Suction, Low-Noise with 12 Filters Solder Fume Extractor for Soldering Laser Engraving Smoke Cleaning

FumeClear FC-2002A Laser Fume Extractor for S1, D1 Pro 10W to 20W Laser Engraver, 260m³/h Strong Suction, Low-Noise with 12 Filters Solder Fume Extractor for Soldering Laser Engraving Smoke Cleaning

FumeClear FC-2003 Dual-port Fume Extractor For 20W 30W Laser Engraving, Low-Noise, Strong Suction 330m³/h, 3-Stage Filtration System With 12 Filters For Soldering, DTF Printer And Beauty Salon

FumeClear FC-2003 Dual-port Fume Extractor For 20W 30W Laser Engraving, Low-Noise, Strong Suction 330m³/h, 3-Stage Filtration System With 12 Filters For Soldering, DTF Printer And Beauty Salon

ACMER AP220 Smoke Air Purifier, 3 Stage Filtration and Timer Switch for P3 24W/48W Laser Engravers, Fume Extractor for Enclosed Laser Cutters

ACMER AP220 Smoke Air Purifier, 3 Stage Filtration and Timer Switch for P3 24W/48W Laser Engravers, Fume Extractor for Enclosed Laser Cutters

xTool F1 Smoke Air Purifier, Fume Extractor with 3-Layer Filtration, Hepa Portable Air Purifier for xTool F1 Laser Engraver

xTool F1 Smoke Air Purifier, Fume Extractor with 3-Layer Filtration, Hepa Portable Air Purifier for xTool F1 Laser Engraver

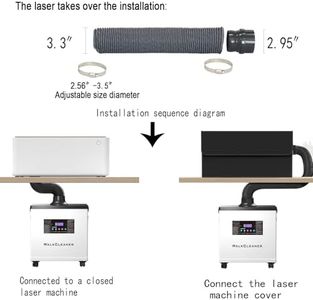

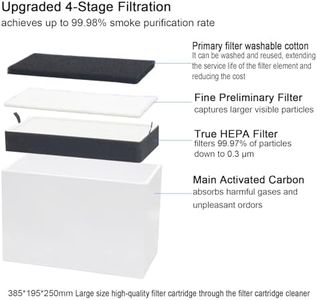

WalkCleaner smoke purifier for laser engraver,laser engraver air purifier, smoke extractor, Fume extractor for laser cutter,Solder Fume Extractor,200w,4-Stage Filtration,99.98% Purification Rate

WalkCleaner smoke purifier for laser engraver,laser engraver air purifier, smoke extractor, Fume extractor for laser cutter,Solder Fume Extractor,200w,4-Stage Filtration,99.98% Purification Rate

WalkCleaner Fume extractor for laser engraver,Laser Fume Extractor Smoke Purifier Smoke Absorber Remover,Solder Fume Extractor,Carbon and HEPA Filter,4-Stage Filtration,99.98% Purification Rate

WalkCleaner Fume extractor for laser engraver,Laser Fume Extractor Smoke Purifier Smoke Absorber Remover,Solder Fume Extractor,Carbon and HEPA Filter,4-Stage Filtration,99.98% Purification Rate

8.5 score

Strong wind 150W Industrial Air Purifier with 3 Layer Air Filter, Fume Extractor for Laser Engraver Exhaust Fans, Portable Smoke Absorber and Purifier

Strong wind 150W Industrial Air Purifier with 3 Layer Air Filter, Fume Extractor for Laser Engraver Exhaust Fans, Portable Smoke Absorber and Purifier

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

![KQZ [Specialized] 210W Laser Fume Extractor 330m³/h Strong Suction for S1/F1/ M1/LU3 Most Laser Engraver, Solder Fume Extractor with Exhaust, Odor Smoke Purifier for Lasering Soldering 3D Printing](https://images-proxy.bestreviews.guide/JthULFj01H5ST179T-674Or9Fn4=/0x300/https://m.media-amazon.com/images/I/41X6VLqb35L._AC_CX679_.jpg)