10 Best Laser Engravers For Wood 2025 in the United States

Winner

xTool F1 Ultra 20W Fiber & Diode Dual Laser Engraver, 10000mm/s Ultra Fast Laser Engraver and Cutter Machine for Jewelry, Metal, Wood, 16MP Smart Camera, Auto Streamline, 3D Engraving Machine

The xTool F1 Ultra 20W Fiber & Diode Dual Laser Engraver is a versatile and powerful machine suitable for both wood and metal engraving. It boasts a significant laser power of 20W for both fiber and diode lasers, allowing it to handle a wide range of materials—from metals like gold and stainless steel to wood, acrylic, and glass. This dual laser system supports intricate 3D embossing and deep engraving, making it a great option for creating high-value items.

Most important from

172 reviews

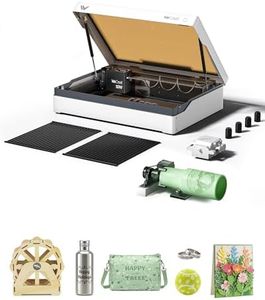

xTool P2S 55W CO2 Laser Cutter, Smart Desktop CO2 Laser Engraver and Cutter Machine, Dual Smart 16MP Cameras, 3D Curved Cylinder Engraving, Create with Wood and Metal Acrylic Glass Fabric Leather

The xTool P2S is a powerful desktop CO2 laser engraver designed for wood and various other materials. It features a strong 55W laser capable of cutting through thick acrylic and wood (up to 18mm in walnut) in one pass, making it suitable for detailed and deep engraving projects. Its large work area of 26" x 14" plus passthrough support allows handling of wide or long pieces, while the riser base option enables engraving on taller objects up to 8.4" high, adding versatility for different project sizes.

Most important from

74 reviews

xTool P2 55W CO2 Laser Cutter, Smart Desktop CO2 Laser Engraver and Cutter Machine, Dual Smart 16MP Cameras, Curved Surface Engraving, Create with Wood and Metal Acrylic Glass Fabric Leather (Gray)

The xTool P2 55W CO2 Laser Cutter is designed for both enthusiasts and professionals in wood and metal engraving, boasting impressive features and capabilities. Its strong 55W laser power enables it to cut through materials like black walnut and acrylic with ease and speed, outperforming many lower-powered options. The engraving area is quite generous at 26"×14", allowing for larger projects and the ability to work with items up to 8.4" high when using the Riser Base, which adds versatility.

Most important from

74 reviews

Top 10 Best Laser Engravers For Wood 2025 in the United States

Winner

10.0 score

xTool F1 Ultra 20W Fiber & Diode Dual Laser Engraver, 10000mm/s Ultra Fast Laser Engraver and Cutter Machine for Jewelry, Metal, Wood, 16MP Smart Camera, Auto Streamline, 3D Engraving Machine

xTool F1 Ultra 20W Fiber & Diode Dual Laser Engraver, 10000mm/s Ultra Fast Laser Engraver and Cutter Machine for Jewelry, Metal, Wood, 16MP Smart Camera, Auto Streamline, 3D Engraving Machine

Chosen by 1311 this week

xTool P2S 55W CO2 Laser Cutter, Smart Desktop CO2 Laser Engraver and Cutter Machine, Dual Smart 16MP Cameras, 3D Curved Cylinder Engraving, Create with Wood and Metal Acrylic Glass Fabric Leather

xTool P2S 55W CO2 Laser Cutter, Smart Desktop CO2 Laser Engraver and Cutter Machine, Dual Smart 16MP Cameras, 3D Curved Cylinder Engraving, Create with Wood and Metal Acrylic Glass Fabric Leather

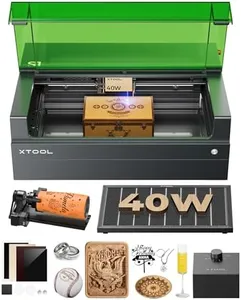

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

xTool S1 40W Laser Cutter and Engraver Machine, with Auto Conveyor Feeder, 118'' Long Crafts, 600mm/s Speed, Laser Engraver for Tumblers Wood and Metal, Acrylic, etc. - Deluxe Bundle

xTool S1 40W Laser Cutter and Engraver Machine, with Auto Conveyor Feeder, 118'' Long Crafts, 600mm/s Speed, Laser Engraver for Tumblers Wood and Metal, Acrylic, etc. - Deluxe Bundle

WECREAT Vision 20W Laser Engraver, Auto-Lifting for 5.5" Material, Smart Camera for Easiest Positioning, 600mm/s Speed, Laser Engraving Machine for Tumblers Metal Wood Acrylic DIY Craft Gifts Making

WECREAT Vision 20W Laser Engraver, Auto-Lifting for 5.5" Material, Smart Camera for Easiest Positioning, 600mm/s Speed, Laser Engraving Machine for Tumblers Metal Wood Acrylic DIY Craft Gifts Making

xTool S1 Laser Engraver and Cutter Machine with Air Assist & Honeycomb, 23.93" x 15.16" Bed Size, Beginner-friendly, Class 1 Safety Laser Engravering Machine for Wood and Metal, Acrylic - Basic Bundle

xTool S1 Laser Engraver and Cutter Machine with Air Assist & Honeycomb, 23.93" x 15.16" Bed Size, Beginner-friendly, Class 1 Safety Laser Engravering Machine for Wood and Metal, Acrylic - Basic Bundle

xTool F1 Lite Laser Engraver, 4000mm/s Lightning Speed Portable Laser Engraving Machine, Ultra HD Laser Engraver for Wood, Leather, Acrylic, Glass, and More.

xTool F1 Lite Laser Engraver, 4000mm/s Lightning Speed Portable Laser Engraving Machine, Ultra HD Laser Engraver for Wood, Leather, Acrylic, Glass, and More.

8.5 score

Creality Falcon A1 10W Laser Engraver, 80W Enclosed Laser Cutter and Engraver Machine with Air Assist, Smart Camera Positioning, 600mm/s Speed, Smart Material Recognition, Ideal for Wood & Metal

Creality Falcon A1 10W Laser Engraver, 80W Enclosed Laser Cutter and Engraver Machine with Air Assist, Smart Camera Positioning, 600mm/s Speed, Smart Material Recognition, Ideal for Wood & Metal

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.