10 Best 20 Gallon Air Compressors 2026 in the United States

Winner

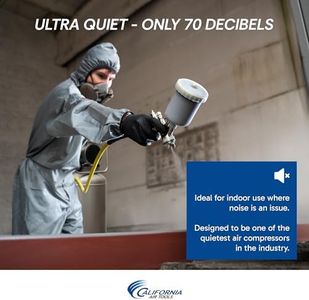

California Air Tools 20020AD 2.0 HP Ultra Quiet and Oil-Free Air Compressor with Wheels, 20 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable, with Automatic Drain Valve

The California Air Tools 20020AD is a 20-gallon air compressor that stands out for its ultra-quiet performance, operating at just 70 dB. This feature makes it suitable for noise-sensitive environments, such as inside a workshop or garage. The compressor boasts a powerful 2.0 HP motor and delivers an impressive 6.40 CFM at 40 PSI and 5.30 CFM at 90 PSI, which is adequate for various tasks like spraying and nailing.

Most important from

239 reviews

Klutch 20-Gallon Air Compressor, 2 HP, 120 Volts, 175 PSI

The Klutch Portable 20-Gallon Air Compressor is designed for consistent and reliable performance, thanks to its 2 HP motor and thermal overload protection. This feature ensures the unit doesn't overheat during extended use, which can help extend its lifespan. It delivers 4.2 CFM at 90 PSI, making it suitable for high-demand applications and helping reduce downtime, which is beneficial for productivity in a workshop or garage setting.

Most important from

450 reviews

California Air Tools 20020-22060 2.0 HP Ultra Quiet and Oil-Free Air Compressor with Wheels, 20 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable, 220 Volts / 60hz

The California Air Tools 20020-22060 is a 20-gallon air compressor that stands out for its ultra-quiet operation, making it suitable for environments where noise is a concern, such as home workshops or small job sites. With a noise level of just 70 dB, it allows you to work without disturbing others. The oil-free dual piston pump not only minimizes maintenance but also enhances the compressor's durability, offering a lifespan of over 3000 hours.

Most important from

239 reviews

Top 10 Best 20 Gallon Air Compressors 2026 in the United States

Winner

California Air Tools 20020AD 2.0 HP Ultra Quiet and Oil-Free Air Compressor with Wheels, 20 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable, with Automatic Drain Valve

California Air Tools 20020AD 2.0 HP Ultra Quiet and Oil-Free Air Compressor with Wheels, 20 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable, with Automatic Drain Valve

Chosen by 1194 this week

Klutch 20-Gallon Air Compressor, 2 HP, 120 Volts, 175 PSI

Klutch 20-Gallon Air Compressor, 2 HP, 120 Volts, 175 PSI

California Air Tools 20020-22060 2.0 HP Ultra Quiet and Oil-Free Air Compressor with Wheels, 20 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable, 220 Volts / 60hz

California Air Tools 20020-22060 2.0 HP Ultra Quiet and Oil-Free Air Compressor with Wheels, 20 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable, 220 Volts / 60hz

California Air Tools 20020AD-22060 2.0 HP Ultra Quiet and Oil-Free Air Compressor with Wheels, 20 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable, with Automatic Drain Valve, 220 V 60 Hz

California Air Tools 20020AD-22060 2.0 HP Ultra Quiet and Oil-Free Air Compressor with Wheels, 20 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable, with Automatic Drain Valve, 220 V 60 Hz

California Air Tools 20020 2.0 HP Ultra Quiet and Oil-Free Air Compressor with Wheels, 20 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable

California Air Tools 20020 2.0 HP Ultra Quiet and Oil-Free Air Compressor with Wheels, 20 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable

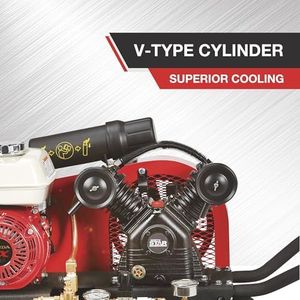

NorthStar Portable Gas-Powered Air Compressor 20-Gal Hor Tank 13.7 CFM @ 90 PSI

NorthStar Portable Gas-Powered Air Compressor 20-Gal Hor Tank 13.7 CFM @ 90 PSI

CAMPBELL HAUSFELD 20 Gallon Gas Powered Air Compressor, Portable Air Compressor, Horizontal, Single Stage, 135 Max PSI, Gas Air Compressor for Versatile On-the-Go Use

CAMPBELL HAUSFELD 20 Gallon Gas Powered Air Compressor, Portable Air Compressor, Horizontal, Single Stage, 135 Max PSI, Gas Air Compressor for Versatile On-the-Go Use

Campbell Hausfeld 20 Gallon Horizontal Air Compressor, Portable Single Stage, 2 HP, Dual Voltage 120/240V, 135 Max PSI, 5.5 CFM at 90 PSI, Ideal for Home Improvement Electric Compressor 20 Gal

Campbell Hausfeld 20 Gallon Horizontal Air Compressor, Portable Single Stage, 2 HP, Dual Voltage 120/240V, 135 Max PSI, 5.5 CFM at 90 PSI, Ideal for Home Improvement Electric Compressor 20 Gal

Craftsman Air Compressor, 20 Gallon Oil-Free 1.8 HP Max 175 PSI Pressure Two Quick Couplers Big Capacity, Red- CMXECXA0232043

Craftsman Air Compressor, 20 Gallon Oil-Free 1.8 HP Max 175 PSI Pressure Two Quick Couplers Big Capacity, Red- CMXECXA0232043

STEALTH 20 Gallon Air Compressor, Ultra Quiet, Oil-Free and Long Life Cycle,1.8 Hp Large Air Compressor with Rubber Wheels (Blue, SAQ-12018)

STEALTH 20 Gallon Air Compressor, Ultra Quiet, Oil-Free and Long Life Cycle,1.8 Hp Large Air Compressor with Rubber Wheels (Blue, SAQ-12018)

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.