10 Best 10 Gallon Air Compressors 2026 in the United States

Winner

California Air Tools 10020C-22060 2.0 HP Ultra Quiet and Oil-Free Air Compressor, 10 Gallon Steel Tank with Wheels, 70 dBA Noise Level, 220 Volt

The California Air Tools 10020C-22060 is a strong contender in the 10-gallon air compressor category, especially if you want quieter, more portable equipment. It has a 2.0 HP motor with a 10-gallon steel tank, which offers a solid balance between power and tank size for various tasks like spraying or light workshop use. Its airflow rates of 6.4 CFM at 40 PSI and 5.3 CFM at 90 PSI mean it can handle many common air tools effectively, although it might struggle with very demanding pneumatic tools that require higher airflow.

Most important from

1595 reviews

California Air Tools 10020C 2.0 HP Ultra Quiet and Oil-Free Air Compressor, 10 Gallon Steel Tank with Wheels, 70 dBA Noise Level

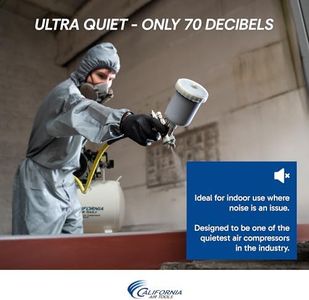

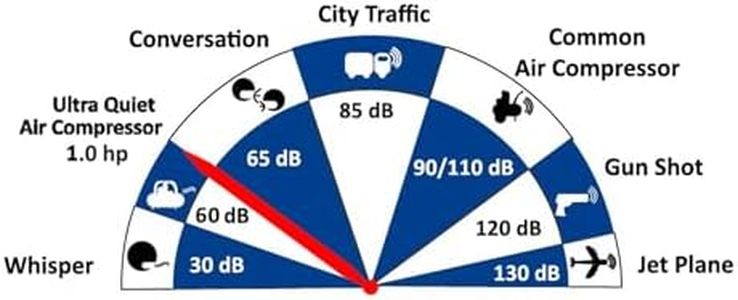

The California Air Tools 10020C is a 10-gallon air compressor designed for those who need a portable and quiet solution for tasks like nailing. One of its standout features is the ultra-quiet operation at 70 dB, making it suitable for use in noise-sensitive environments. The powerful 2.0 HP motor running at a low 1680 RPM reduces wear and noise, contributing to its durability and long life cycle of over 3000 hours.

Most important from

1595 reviews

California Air Tools 10020CHAD 2.0 HP Ultra Quiet, Oil-Free Air Compressor, 10 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable, with Automatic Drain Valve

The California Air Tools 10020CHAD is a 10-gallon air compressor known for its ultra-quiet performance, emitting only 70 dB of noise, making it suitable for noise-sensitive environments. This is a significant advantage for those who need to work in quiet areas or at home. The compressor is powered by a 2.0 HP motor, providing a substantial amount of power while maintaining a low noise level. With a CFM of 6.40 at 40 PSI and 5.30 at 90 PSI, it offers a decent air flow capacity suitable for tasks like drilling, air brushing, and nailing. The oil-free dual piston pump design is another highlight, as it reduces maintenance requirements and ensures cleaner air, appealing to users looking for long-term reliability and ease of use.

Most important from

59 reviews

Top 10 Best 10 Gallon Air Compressors 2026 in the United States

Winner

California Air Tools 10020C-22060 2.0 HP Ultra Quiet and Oil-Free Air Compressor, 10 Gallon Steel Tank with Wheels, 70 dBA Noise Level, 220 Volt

California Air Tools 10020C-22060 2.0 HP Ultra Quiet and Oil-Free Air Compressor, 10 Gallon Steel Tank with Wheels, 70 dBA Noise Level, 220 Volt

Chosen by 1440 this week

California Air Tools 10020C 2.0 HP Ultra Quiet and Oil-Free Air Compressor, 10 Gallon Steel Tank with Wheels, 70 dBA Noise Level

California Air Tools 10020C 2.0 HP Ultra Quiet and Oil-Free Air Compressor, 10 Gallon Steel Tank with Wheels, 70 dBA Noise Level

California Air Tools 10020CHAD 2.0 HP Ultra Quiet, Oil-Free Air Compressor, 10 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable, with Automatic Drain Valve

California Air Tools 10020CHAD 2.0 HP Ultra Quiet, Oil-Free Air Compressor, 10 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable, with Automatic Drain Valve

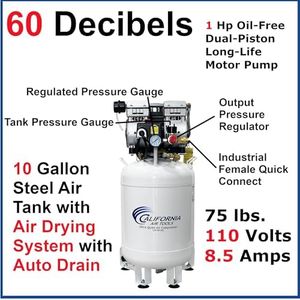

California Air Tools 10010DCAD Ultra Quiet & Oil-Free Steel Tank Air Compressor with Drying System and Auto Drain Valve, 10 gallon

California Air Tools 10010DCAD Ultra Quiet & Oil-Free Steel Tank Air Compressor with Drying System and Auto Drain Valve, 10 gallon

California Air Tools 10020CHAD-22060 2.0 HP Ultra Quiet, Oil-Free Air Compressor, 10 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable, with Automatic Drain Valve, 220V / 60Hz

California Air Tools 10020CHAD-22060 2.0 HP Ultra Quiet, Oil-Free Air Compressor, 10 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable, with Automatic Drain Valve, 220V / 60Hz

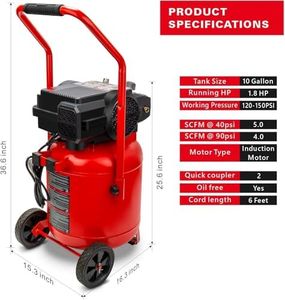

Craftsman Air Compressor 10 Gallon, Peak 1.8 HP, Max 150 PSI, Oil-free, Portable Air Compressor with Wheel, Small Air Compressor for Use with Framing, Siding, Finish, Brad or Roofing Nailers

Craftsman Air Compressor 10 Gallon, Peak 1.8 HP, Max 150 PSI, Oil-free, Portable Air Compressor with Wheel, Small Air Compressor for Use with Framing, Siding, Finish, Brad or Roofing Nailers

VEVOR Air Compressor, 10 Gallon Steel Tank, 2HP 5.3 CFM@90 PSI Oil Free Air Compressor & Max. 125PSI Pressure, 78dB Ultra Quiet Portable Compressor, for Auto Repair, Tire Inflation, Spray Painting

VEVOR Air Compressor, 10 Gallon Steel Tank, 2HP 5.3 CFM@90 PSI Oil Free Air Compressor & Max. 125PSI Pressure, 78dB Ultra Quiet Portable Compressor, for Auto Repair, Tire Inflation, Spray Painting

California Air Tools CAT-10020AC 2.0 HP Ultra Quiet, Oil-Free, Lightweight Air Compressor with Wheels, 10 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable

California Air Tools CAT-10020AC 2.0 HP Ultra Quiet, Oil-Free, Lightweight Air Compressor with Wheels, 10 Gallon Tank Capacity, 70 dB Noise Level, Electric, Portable

10 Gallon Ultra Quiet Air Compressor with Two Quick Couplers, 2HP 8.76 CFM@ 115PSI Pressure Oil-Free Air Compressor Tank, 70dB Quiet Compressor for Auto Repair, Tire Inflation 110V/60hz

10 Gallon Ultra Quiet Air Compressor with Two Quick Couplers, 2HP 8.76 CFM@ 115PSI Pressure Oil-Free Air Compressor Tank, 70dB Quiet Compressor for Auto Repair, Tire Inflation 110V/60hz

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.