10 Best Tubing Notcher 2025 in the United States

Winner

KAKA INDUSTRIAL RA-5 Manual Pipe Notcher, 1", 1-1/4", 1-1/2" (Inside diameter) Notcher Capacity, Light Weight, 90 Degree High Precision Steel Tube Notcher, Steel Tube and Pipe Notcher

The KAKA INDUSTRIAL RA-5 Manual Pipe Notcher is designed for those who need a reliable tool for notching steel pipes and tubes with diameters of 1", 1-1/4", and 1-1/2". One of its key strengths is the high precision it offers, which is essential for clean and accurate cuts, especially when preparing joints for welding. Users will also appreciate its lightweight design, making it easy to handle and operate in various positions, whether vertically or horizontally. The manual operation simplifies usage, making it accessible for both beginners and seasoned professionals alike.

Most important from

43 reviews

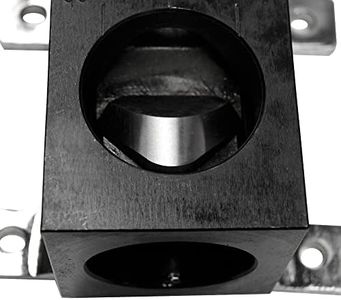

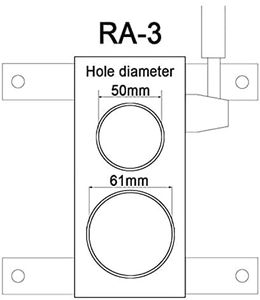

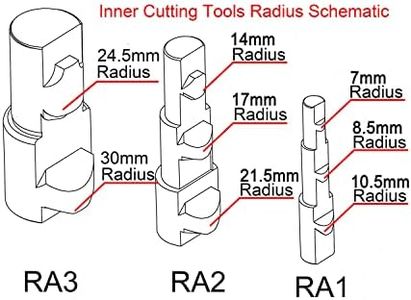

KAKA INDUSTRIAL RA-3 Manual Pipe Notcher, 1-1/2", 2" (Inside diameter) Capacity, Light Weight, Solid Construction Pipe Notcher

The KAKA INDUSTRIAL RA-3 Manual Pipe Notcher is a solid choice for DIY enthusiasts and professionals looking for a reliable notching tool. It is designed to accommodate pipes with an inside diameter of 1-1/2" and 2", making it suitable for various tubing projects. One of its main strengths is its lightweight design, which, combined with the ability to operate both vertically and horizontally, enhances its versatility and ease of use. Users will appreciate how straightforward it is to set up and adjust for different notching angles, allowing for precise cuts necessary for jointing pipes effectively.

Most important from

43 reviews

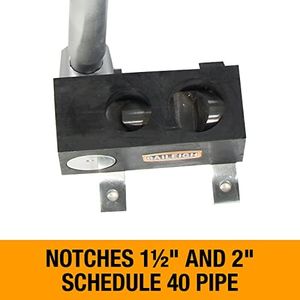

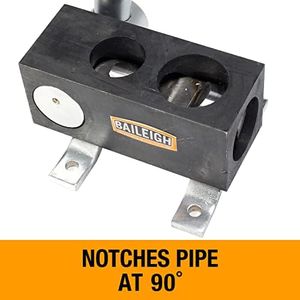

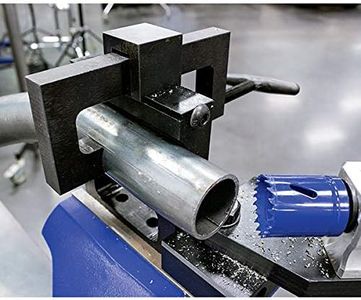

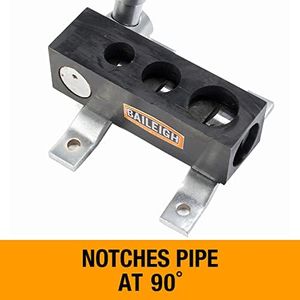

Baileigh Manual Pipe Notcher (TN-200M)

The Baileigh Manual Pipe Notcher (TN-200M) is designed for users who need to create precise notches in 1.5” and 2” schedule 40 pipes at a 90° angle. One of its main strengths is the high-quality chromium blades, which are known for producing excellent notches and maintaining their sharpness over time. The fully-machined steel housing adds to the notcher's durability, ensuring that it can withstand regular use without losing accuracy, making it a reliable choice for both professionals and DIY enthusiasts.

Most important from

6 reviews

Top 10 Best Tubing Notcher 2025 in the United States

Winner

KAKA INDUSTRIAL RA-5 Manual Pipe Notcher, 1", 1-1/4", 1-1/2" (Inside diameter) Notcher Capacity, Light Weight, 90 Degree High Precision Steel Tube Notcher, Steel Tube and Pipe Notcher

KAKA INDUSTRIAL RA-5 Manual Pipe Notcher, 1", 1-1/4", 1-1/2" (Inside diameter) Notcher Capacity, Light Weight, 90 Degree High Precision Steel Tube Notcher, Steel Tube and Pipe Notcher

Chosen by 1209 this week

KAKA INDUSTRIAL RA-3 Manual Pipe Notcher, 1-1/2", 2" (Inside diameter) Capacity, Light Weight, Solid Construction Pipe Notcher

KAKA INDUSTRIAL RA-3 Manual Pipe Notcher, 1-1/2", 2" (Inside diameter) Capacity, Light Weight, Solid Construction Pipe Notcher

Baileigh Manual Pipe Notcher (TN-200M)

Baileigh Manual Pipe Notcher (TN-200M)

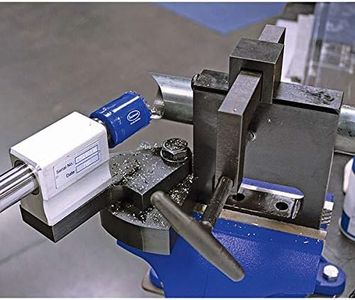

Jeremywell Industrial Professional Pipe & Tube Notcher Punch and Press Tool, Aluminum Made, Heavy Duty, for 0-50 Degree Angle, Notches 3/4" - 3" Round Tubing Bore Hole

Jeremywell Industrial Professional Pipe & Tube Notcher Punch and Press Tool, Aluminum Made, Heavy Duty, for 0-50 Degree Angle, Notches 3/4" - 3" Round Tubing Bore Hole

KASTFORCE KF5008 2 Inch Hole Saw Pipe Tube Notcher Tubing Notcher - Adjustable up to 60 Degree

KASTFORCE KF5008 2 Inch Hole Saw Pipe Tube Notcher Tubing Notcher - Adjustable up to 60 Degree

Eastwood Professional Tubing Notcher Tube and Pipe Notcher Steel Adjustable Up to 50 Degreess

Eastwood Professional Tubing Notcher Tube and Pipe Notcher Steel Adjustable Up to 50 Degreess

Baileigh Hole Saw Notcher (TN-210H)

Baileigh Hole Saw Notcher (TN-210H)

Heck Pipe and Tube Notcher, Hole Saw, 40 ga.

Heck Pipe and Tube Notcher, Hole Saw, 40 ga.

Baileigh Manual Pipe Notcher (TN-125M)

Baileigh Manual Pipe Notcher (TN-125M)

HHIP 8600-4046 1-1/16" - 1-11/16" Tube Notcher

HHIP 8600-4046 1-1/16" - 1-11/16" Tube Notcher

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.