10 Best Retractable Ratchet Straps 2025 in the United States

Winner

Rhino USA Retractable Ratchet Straps (4-Pack) - 1 Inch x 10 Feet (1,209lb Break Strength) - Heavy Duty Auto Self Retracting Tie Down Straps for Truck, Cargo Trailer, Motorcycle, Rad & More - Gray

The Rhino USA Retractable Ratchet Straps (4-pack) offer a reliable, easy-to-use solution for securing cargo such as trailers, motorcycles, and other loads. Each strap is 1 inch wide and 10 feet long, providing a good balance of length and manageability for most tie-down tasks. With a load capacity of 403 pounds per strap and a break strength of 1,209 pounds, these straps are designed to safely hold moderate loads without worry.

Most important from

5274 reviews

Rhino USA Retractable Boat Trailer Tie Down Straps 2PK – Durable (2in x 43in) Trailer Mount Transom Straps for Boat, Jet Ski – Stainless Steel – Salt Water Compatible

The Rhino USA Retractable Heavy Duty Boat Tie Down Straps are designed specifically for securing boats and jet skis to trailers. These straps feature a load capacity of 1011 pounds and are made from heavy-duty poly/silk webbing, ensuring durability and strength. The strap length is 43 inches and the width is 2 inches, making them suitable for various watercraft sizes. Additionally, the stainless steel ratchet mechanism and hooks are corrosion-resistant, which is particularly beneficial for saltwater environments, enhancing the product's longevity and reliability.

Rhino USA Retractable Ratchet Straps (2-Pack) - 2 Inch x 10 Feet (3,033lb Break Strength) - Heavy Duty Auto Self Retracting Tie Down Straps for Truck, Cargo Trailer, Motorcycle, Rad & More - Gray

The Rhino USA Retractable Ratchet Straps come as a 2-pack with each strap measuring 2 inches wide and 10 feet long, suitable for securing various loads on trucks, trailers, motorcycles, or other cargo. Each strap has a load capacity of 1,011 pounds and a break strength of 3,033 pounds, making them strong enough for heavy-duty use without being overly bulky. Made from durable polyester, the straps include a ratchet mechanism with an electro-plated zinc coating and an ergonomic padded handle, providing both durability and comfortable handling.

Most important from

2984 reviews

Top 10 Best Retractable Ratchet Straps 2025 in the United States

Sponsored

Winner

9.8 score

Rhino USA Retractable Ratchet Straps (4-Pack) - 1 Inch x 10 Feet (1,209lb Break Strength) - Heavy Duty Auto Self Retracting Tie Down Straps for Truck, Cargo Trailer, Motorcycle, Rad & More - Gray

Rhino USA Retractable Ratchet Straps (4-Pack) - 1 Inch x 10 Feet (1,209lb Break Strength) - Heavy Duty Auto Self Retracting Tie Down Straps for Truck, Cargo Trailer, Motorcycle, Rad & More - Gray

Chosen by 1430 this week

Sponsored

Rhino USA Retractable Boat Trailer Tie Down Straps 2PK – Durable (2in x 43in) Trailer Mount Transom Straps for Boat, Jet Ski – Stainless Steel – Salt Water Compatible

Rhino USA Retractable Boat Trailer Tie Down Straps 2PK – Durable (2in x 43in) Trailer Mount Transom Straps for Boat, Jet Ski – Stainless Steel – Salt Water Compatible

Rhino USA Retractable Ratchet Straps (2-Pack) - 2 Inch x 10 Feet (3,033lb Break Strength) - Heavy Duty Auto Self Retracting Tie Down Straps for Truck, Cargo Trailer, Motorcycle, Rad & More - Gray

Rhino USA Retractable Ratchet Straps (2-Pack) - 2 Inch x 10 Feet (3,033lb Break Strength) - Heavy Duty Auto Self Retracting Tie Down Straps for Truck, Cargo Trailer, Motorcycle, Rad & More - Gray

AUGO Ratchet Straps Heavy Duty 4 Pack -15 FT - 2200 LB Break Strength – with Safety Lock S Hooks - Cargo Straps for Moving, Appliances, Motorcycle – Soft Loop Tie Down Straps

AUGO Ratchet Straps Heavy Duty 4 Pack -15 FT - 2200 LB Break Strength – with Safety Lock S Hooks - Cargo Straps for Moving, Appliances, Motorcycle – Soft Loop Tie Down Straps

AUGO Retractable Ratchet Straps | 4 Heavy Duty Ratchet Straps Self Retractable Tie Down Straps with Soft Loops & Storage Bag for Motorcycle, Truck, Trailer, Cargo Van | 1200 Lb Break Strength 1” x 10’

AUGO Retractable Ratchet Straps | 4 Heavy Duty Ratchet Straps Self Retractable Tie Down Straps with Soft Loops & Storage Bag for Motorcycle, Truck, Trailer, Cargo Van | 1200 Lb Break Strength 1” x 10’

DC Cargo Mall Retractable Ratchet Strap, 4 Pack (1 inch x 6 feet) - Heavy Duty Tie Down Retractable Ratchet Straps - Easy Self Contained Black Ratchet Strap Tie Downs for Trailers, Vehicles, Boat

DC Cargo Mall Retractable Ratchet Strap, 4 Pack (1 inch x 6 feet) - Heavy Duty Tie Down Retractable Ratchet Straps - Easy Self Contained Black Ratchet Strap Tie Downs for Trailers, Vehicles, Boat

SMARTSTRAPS 10’ Retractable Ratchet Straps, 2 Pack – 3,000lb Break Strength, 1,000lb Safe Work Load — Haul Motorcycles, Boats, and Appliances with Patented Technology Heavy Duty Ratchet Straps

SMARTSTRAPS 10’ Retractable Ratchet Straps, 2 Pack – 3,000lb Break Strength, 1,000lb Safe Work Load — Haul Motorcycles, Boats, and Appliances with Patented Technology Heavy Duty Ratchet Straps

Retractable Ratchet Straps (4PK 1.0INX12FT) - 1,500lb Break Strength, Heavy Duty with Rubber Coated Handle, Perfect for Motorcycle & Trucks (Blue)

Retractable Ratchet Straps (4PK 1.0INX12FT) - 1,500lb Break Strength, Heavy Duty with Rubber Coated Handle, Perfect for Motorcycle & Trucks (Blue)

SMARTSTRAPS Retractable Ratchet Tie Down Straps (4 PK) 1,500lb Break Strength, 500lb Safe Work Load, Standard Duty, Secure and Haul ATVs, Lawn Tractors, Cargo, Boxes and Other Small Equipment

SMARTSTRAPS Retractable Ratchet Tie Down Straps (4 PK) 1,500lb Break Strength, 500lb Safe Work Load, Standard Duty, Secure and Haul ATVs, Lawn Tractors, Cargo, Boxes and Other Small Equipment

7.4 score

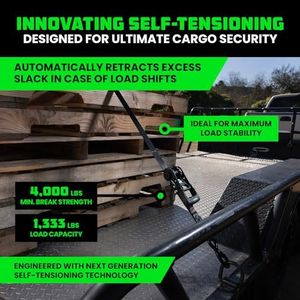

Rhino USA Self Tensioning Ratchet Tie Down Straps (2PK 1.6INX15FT) - Heavy Duty Patented Cargo Strap Keeps Tension When Your Load Shifts - Used for Motorcycle, ATV, UTV, Truck, General Cargo & More

Rhino USA Self Tensioning Ratchet Tie Down Straps (2PK 1.6INX15FT) - Heavy Duty Patented Cargo Strap Keeps Tension When Your Load Shifts - Used for Motorcycle, ATV, UTV, Truck, General Cargo & More

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.