10 Best Rebar Cutters 2025 in the United States

Winner

Metabo HPT Portable Rebar Bender and Cutter, 8-Amp Motor, Grade 60 rebar, Maximum 180° Angle, Variable Speed Trigger, Lightweight Design, Precision Bends and Cuts, VB16Y

The Metabo HPT Rebar Bender and Cutter stands out as a versatile tool for those working with rebar, offering both cutting and bending capabilities. One of its key strengths is the powerful 8-Amp electric motor, which allows for quick operations, making it suitable for professional work environments where efficiency is crucial. The tool can bend rebar up to #5 Grade 60, which includes sizes 3/8", 1/2", and 5/8", and does so in a mere 5.1 seconds. Cutting is equally efficient, taking just 3.1 seconds, and the high durability cutting blades are a significant advantage as they can exceed 5,000 cuts before needing replacement.

Most important from

115 reviews

Metabo HPT 36V MultiVolt Portable Rebar Bender/Cutter, Dual Power Source Technology, Fast Cuts, Powerful Bends, Brushless Motor, Includes 2x 4.0Ah Metabo Batteries and Rapid Charger, VB3616DA

The Metabo HPT 36V MultiVolt™ Cordless Rebar Bender/Cutter is designed for professionals and DIY enthusiasts who need a reliable tool for cutting and bending rebar. One of its standout features is its impressive cutting capacity, allowing users to make around 270 cuts on #5 rebar per charge. This makes it a great choice for heavy-duty tasks. The brushless motor contributes to quick cuts, taking less than three seconds, which enhances efficiency on the job site. Additionally, the dual-step trigger and deflection guard increase safety during operation, making it user-friendly.

Most important from

115 reviews

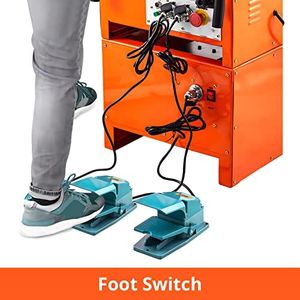

Electric Rebar Bender & Cutter Machine Rebar Steel Bender 1''/25 mm Max Rebar Diameter, Bending Machine For Bending Rebar, Steel Bar, Steel Rod (1600W Rebar Bender and Cutter)

This electric rebar bender and cutter machine is designed for handling rebar up to 1 inch (25 mm) in diameter, which fits well for most common construction needs. It uses a powerful 1600W pure copper motor that runs quietly and is built to last, helping improve work speed and reduce wear over time. The machine bends rebar quickly, generally between 6 to 7 seconds, and cuts within 5 to 6 seconds, making it efficient for repetitive tasks. Its ability to bend angles from 0 to 180 degrees with preset locks adds precision and versatility.

Top 10 Best Rebar Cutters 2025 in the United States

Winner

Metabo HPT Portable Rebar Bender and Cutter, 8-Amp Motor, Grade 60 rebar, Maximum 180° Angle, Variable Speed Trigger, Lightweight Design, Precision Bends and Cuts, VB16Y

Metabo HPT Portable Rebar Bender and Cutter, 8-Amp Motor, Grade 60 rebar, Maximum 180° Angle, Variable Speed Trigger, Lightweight Design, Precision Bends and Cuts, VB16Y

Chosen by 1270 this week

Metabo HPT 36V MultiVolt Portable Rebar Bender/Cutter, Dual Power Source Technology, Fast Cuts, Powerful Bends, Brushless Motor, Includes 2x 4.0Ah Metabo Batteries and Rapid Charger, VB3616DA

Metabo HPT 36V MultiVolt Portable Rebar Bender/Cutter, Dual Power Source Technology, Fast Cuts, Powerful Bends, Brushless Motor, Includes 2x 4.0Ah Metabo Batteries and Rapid Charger, VB3616DA

Electric Rebar Bender & Cutter Machine Rebar Steel Bender 1''/25 mm Max Rebar Diameter, Bending Machine For Bending Rebar, Steel Bar, Steel Rod (1600W Rebar Bender and Cutter)

Electric Rebar Bender & Cutter Machine Rebar Steel Bender 1''/25 mm Max Rebar Diameter, Bending Machine For Bending Rebar, Steel Bar, Steel Rod (1600W Rebar Bender and Cutter)

Makita XCS04T1 18V LXT® Lithium-Ion Brushless Cordless Rebar Cutter Kit (5.0Ah)

Makita XCS04T1 18V LXT® Lithium-Ion Brushless Cordless Rebar Cutter Kit (5.0Ah)

Rebar Cutter/Bender, 180 Deg, 10Amp, 5/8Cap

Rebar Cutter/Bender, 180 Deg, 10Amp, 5/8Cap

Multiquip Bon Rebar Cutter - 3/4" 115V Electric (35-311)

Multiquip Bon Rebar Cutter - 3/4" 115V Electric (35-311)

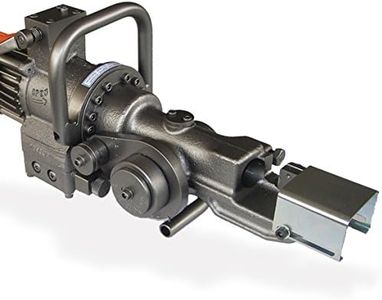

BN Products Portable Rebar Cutter - Electric/Hydraulic, Cuts 3/4in. Rebar, Model Number DC-20WH

BN Products Portable Rebar Cutter - Electric/Hydraulic, Cuts 3/4in. Rebar, Model Number DC-20WH

VEVOR Electric Rebar Cutter, 1700W Portable Electric Hydraulic Rebar Cutter, Cutting up to 1 Inch #8 4-25mm Rebar within 5 Seconds,110V,with Easy to Carry Stainless Box

VEVOR Electric Rebar Cutter, 1700W Portable Electric Hydraulic Rebar Cutter, Cutting up to 1 Inch #8 4-25mm Rebar within 5 Seconds,110V,with Easy to Carry Stainless Box

Makita DTR181ZJ 18V Li-ion LXT Brushless Rebar Cutting Tool Supplied in a Makpac Case – Batteries and Charger Not Included

Makita DTR181ZJ 18V Li-ion LXT Brushless Rebar Cutting Tool Supplied in a Makpac Case – Batteries and Charger Not Included

VEVOR Electric Hydraulic Rebar Bender, 1500W Portable Rebar Bending Machine, Bending up to 3/4 Inch #6 (6-20mm) within 4 Seconds, High Power Steel Rebar Bender w/Tool Case Oil Can,Black Blue RN-22

VEVOR Electric Hydraulic Rebar Bender, 1500W Portable Rebar Bending Machine, Bending up to 3/4 Inch #6 (6-20mm) within 4 Seconds, High Power Steel Rebar Bender w/Tool Case Oil Can,Black Blue RN-22

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.