10 Best Plasma Cutter For Cnc Table 2025 in the United States

Winner

ARCCAPTAIN Plasma Cutter, [Large LED Display] 50Amps Cutter Machine with 110/220V Dual Voltage DC Inverter IGBT 1/2 Inch Clean Cut Post Flow and 2T/4T, for Beginners DIY

The ARCCAPTAIN Plasma Cutter is designed for users, especially beginners and DIY enthusiasts, who need a reliable tool for cutting various metals with ease. One of its standout features is the dual-voltage capability (110/220V), which enhances its versatility for different power settings. The cutting performance is impressive, with a maximum severance cut of 3/4 inch and an ideal clean cut at 1/2 inch. Its 60% duty cycle makes it suitable for moderate jobs without overheating, which is a plus for those needing to work efficiently.

Most important from

990 reviews

ARCCAPTAIN iControl Cut55 Pro Plasma Cutter, [APP Control] 55 Amp Non-Touch Pilot Arc 120V/240V Plasma Cutter Machine, Large LED Display and 2T/4T, 3/4 inch Maximum Cut, DC Inverter IGBT

The ARCCAPTAIN iControl Cut55 Pro is a solid option for a plasma cutter designed for CNC table use, especially if you want digital control and convenience. It supports cutting thickness up to 20mm (3/4 inch), which covers most medium-duty metal cutting tasks. Its non-touch pilot arc allows you to cut through rusty or coated steel without damaging the torch, which is great for maintaining tool life and handling less-than-perfect metals. The machine runs on both 120V and 240V, offering flexibility for different workshop setups. Its inverter technology ensures stable cutting performance and efficient power use.

Most important from

182 reviews

bestarc Plasma Cutter, [Pilot Arc] [Large LED Display] [Air Sensor Technology] 50Amps Cutter Machine 110/220V Dual Voltage IGBT Inverter 5/8 Inch Clean Cut, Post Flow 2T/4T for Home DIY BTC500DP

The bestarc Plasma Cutter BTC500DP 7Gen is a solid choice for those looking to engage in CNC cutting work. One of its standout features is the pilot arc function, which allows for non-touch arc starting, making it easier to cut through metal without needing the torch to physically contact the workpiece. This can enhance the longevity of the consumables and reduce energy waste during non-cutting operations.

Most important from

2255 reviews

Top 10 Best Plasma Cutter For Cnc Table 2025 in the United States

Winner

9.8 score

ARCCAPTAIN Plasma Cutter, [Large LED Display] 50Amps Cutter Machine with 110/220V Dual Voltage DC Inverter IGBT 1/2 Inch Clean Cut Post Flow and 2T/4T, for Beginners DIY

ARCCAPTAIN Plasma Cutter, [Large LED Display] 50Amps Cutter Machine with 110/220V Dual Voltage DC Inverter IGBT 1/2 Inch Clean Cut Post Flow and 2T/4T, for Beginners DIY

Chosen by 1143 this week

ARCCAPTAIN iControl Cut55 Pro Plasma Cutter, [APP Control] 55 Amp Non-Touch Pilot Arc 120V/240V Plasma Cutter Machine, Large LED Display and 2T/4T, 3/4 inch Maximum Cut, DC Inverter IGBT

ARCCAPTAIN iControl Cut55 Pro Plasma Cutter, [APP Control] 55 Amp Non-Touch Pilot Arc 120V/240V Plasma Cutter Machine, Large LED Display and 2T/4T, 3/4 inch Maximum Cut, DC Inverter IGBT

bestarc Plasma Cutter, [Pilot Arc] [Large LED Display] [Air Sensor Technology] 50Amps Cutter Machine 110/220V Dual Voltage IGBT Inverter 5/8 Inch Clean Cut, Post Flow 2T/4T for Home DIY BTC500DP

bestarc Plasma Cutter, [Pilot Arc] [Large LED Display] [Air Sensor Technology] 50Amps Cutter Machine 110/220V Dual Voltage IGBT Inverter 5/8 Inch Clean Cut, Post Flow 2T/4T for Home DIY BTC500DP

YESWELDER 55 Amp Plasma Cutter Non-High Frequency, Large LED Digital Display Non-Touch Pilot Arc, Digital DC Inverter 110/220V Dual Voltage Plasma Cutting Machine CUT-55DS PRO NEW

YESWELDER 55 Amp Plasma Cutter Non-High Frequency, Large LED Digital Display Non-Touch Pilot Arc, Digital DC Inverter 110/220V Dual Voltage Plasma Cutting Machine CUT-55DS PRO NEW

SILATU CNC Plasma Cutter Machine, 85Amp Blow Back Pilot Arc Air Sensor Technology, Large Screen Display,110V/220V Dual Voltage Non-Touch CNC Plasma Cutting Machine, 1 Inch Cutting Thickness

SILATU CNC Plasma Cutter Machine, 85Amp Blow Back Pilot Arc Air Sensor Technology, Large Screen Display,110V/220V Dual Voltage Non-Touch CNC Plasma Cutting Machine, 1 Inch Cutting Thickness

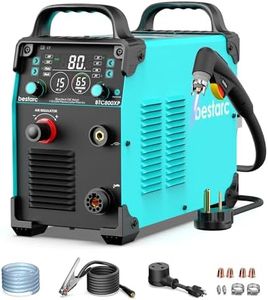

bestarc Plasma Cutter, 80Amp Blow Back Pilot Arc [Air Sensor Technology] Plasma Cutter, 110V/220V Dual Voltage Non-HF CNC Plasma Cutting Machine, Digital Screen Display (BTC800XP 11GEN 110V/220V)

bestarc Plasma Cutter, 80Amp Blow Back Pilot Arc [Air Sensor Technology] Plasma Cutter, 110V/220V Dual Voltage Non-HF CNC Plasma Cutting Machine, Digital Screen Display (BTC800XP 11GEN 110V/220V)

Hypertherm Powermax 65 SYNC Plasma Cutter w/CPC Port, 25 ft. 180 Degree Machine Torch 083349

Hypertherm Powermax 65 SYNC Plasma Cutter w/CPC Port, 25 ft. 180 Degree Machine Torch 083349

Hypertherm Powermax 85 SYNC Plasma Cutter w/CPC Port, 25 ft. 180 Degree Machine Torch 087189

Hypertherm Powermax 85 SYNC Plasma Cutter w/CPC Port, 25 ft. 180 Degree Machine Torch 087189

7.5 score

Miller 907579001 Spectrum 625 X-TREME Plasma Cutter Machine - Plasma Cutting Equipment with XT40 Torch & 20-ft. Cable - Portable Plasma Cutters 120/240V 40 Amps Cuts Up to 5/8" Mild Steel (21 lbs)

Miller 907579001 Spectrum 625 X-TREME Plasma Cutter Machine - Plasma Cutting Equipment with XT40 Torch & 20-ft. Cable - Portable Plasma Cutters 120/240V 40 Amps Cuts Up to 5/8" Mild Steel (21 lbs)

Recommended lists

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

![ARCCAPTAIN Plasma Cutter, [Large LED Display] 50Amps Cutter Machine with 110/220V Dual Voltage DC Inverter IGBT 1/2 Inch Clean Cut Post Flow and 2T/4T, for Beginners DIY](https://images-proxy.bestreviews.guide/6BQxNu10H7g3hMmwNIGR4w36Lgk=/0x300/https://m.media-amazon.com/images/I/41nB1Wxee0L._AC_CX679_.jpg)

![ARCCAPTAIN iControl Cut55 Pro Plasma Cutter, [APP Control] 55 Amp Non-Touch Pilot Arc 120V/240V Plasma Cutter Machine, Large LED Display and 2T/4T, 3/4 inch Maximum Cut, DC Inverter IGBT](https://images-proxy.bestreviews.guide/554zZIVfi1wrM1L8l8leBKhEkMI=/0x300/https://m.media-amazon.com/images/I/51naxqQVKfL._AC_CX679_.jpg)

![bestarc Plasma Cutter, [Pilot Arc] [Large LED Display] [Air Sensor Technology] 50Amps Cutter Machine 110/220V Dual Voltage IGBT Inverter 5/8 Inch Clean Cut, Post Flow 2T/4T for Home DIY BTC500DP](https://images-proxy.bestreviews.guide/ASJPDobAqYjp5M4mVKPyoHhFTm4=/0x300/https://m.media-amazon.com/images/I/41VvRHcpNJL._AC_CX679_.jpg)

![ARCCAPTAIN iControl Cut55 Pro Plasma Cutter, [APP Control] 55 Amp Non-Touch Pilot Arc 110V/220V Plasma Cutter Machine, Large LED Display and 2T/4T, 3/4 inch Maximum Cut, DC Inverter IGBT](https://images-proxy.bestreviews.guide/SDWoibZjscM40LvmawRdJcnUpyM=/0x300/https://m.media-amazon.com/images/I/51FAl0HNQhL._AC_CX679_.jpg)