10 Best Magnetic Drill Presses 2026 in the United States

Winner

Milwaukee 278822HD M18 FUEL 1-1/2 in. Lineman Magnetic Drill Kit

The Milwaukee 278822HD M18 FUEL Magnetic Drill Kit stands out in the magnetic drill press category, specifically for those who need reliability and power in their drilling tasks. One of its strongest features is the self-powered magnet base, which can deliver an impressive 2,000 lbs. of holding force, allowing you to work with confidence on various metal surfaces without worrying about stability. The brushless motor contributes to a longer motor life and enhanced performance, which is beneficial for heavy-duty tasks.

Most important from

4 reviews

Hougen HMD904S 115-Volt Swivel Base Magnetic Drill Fabricator's Kit with Integrated Coolant Bottle Plus 1/2" Drill Chuck, Adapter, and 12002 Rotabroach Cutter Kit

The Hougen HMD904S Magnetic Drill Press is a versatile and powerful tool designed for fabricators. It offers a solid magnetic strength thanks to its two-stage magnet which increases power by 30% when the motor is on, ensuring a secure and stable drilling experience. The motor delivers 9 amps of power and a maximum speed of 450 RPM, which is suitable for various drilling tasks. The drill has a decent capacity of 1.5 inches, making it capable of handling substantial metal drilling jobs.

ZELCAN Magnetic Drill Press with 11 Drill Bits, 1550W Mag Drill Press with 2" Dia. 3125 lbf/13900N Mag Force, 650 rpm Power Magnetic Drill with Stepless Speed & Reversible Direction for Metal Surface

The ZELCAN Magnetic Drill Press is a solid choice for those needing a portable yet powerful tool for drilling into metal surfaces. It features a strong 1550W copper motor, which delivers enough power to comfortably drill holes up to 2 inches in diameter and depth. Its maximum drill speed of 650 RPM is suitable for many metalworking tasks, and the stepless speed control allows you to precisely adjust the speed to fit different materials and jobs.

Most important from

179 reviews

Top 10 Best Magnetic Drill Presses 2026 in the United States

Winner

Milwaukee 278822HD M18 FUEL 1-1/2 in. Lineman Magnetic Drill Kit

Milwaukee 278822HD M18 FUEL 1-1/2 in. Lineman Magnetic Drill Kit

Chosen by 1296 this week

Hougen HMD904S 115-Volt Swivel Base Magnetic Drill Fabricator's Kit with Integrated Coolant Bottle Plus 1/2" Drill Chuck, Adapter, and 12002 Rotabroach Cutter Kit

Hougen HMD904S 115-Volt Swivel Base Magnetic Drill Fabricator's Kit with Integrated Coolant Bottle Plus 1/2" Drill Chuck, Adapter, and 12002 Rotabroach Cutter Kit

ZELCAN Magnetic Drill Press with 11 Drill Bits, 1550W Mag Drill Press with 2" Dia. 3125 lbf/13900N Mag Force, 650 rpm Power Magnetic Drill with Stepless Speed & Reversible Direction for Metal Surface

ZELCAN Magnetic Drill Press with 11 Drill Bits, 1550W Mag Drill Press with 2" Dia. 3125 lbf/13900N Mag Force, 650 rpm Power Magnetic Drill with Stepless Speed & Reversible Direction for Metal Surface

20V MAX FVA 2 IN MAGNETIC DRILL KIT

20V MAX FVA 2 IN MAGNETIC DRILL KIT

Fein JCM 256 U Magnetic Drill Unit up to 2-1/2"

Fein JCM 256 U Magnetic Drill Unit up to 2-1/2"

Magnetic Drill Press Kit, 14 in. H

Magnetic Drill Press Kit, 14 in. H

Hougen HMD904 115-Volt Magnetic Drill

Hougen HMD904 115-Volt Magnetic Drill

Makita HB350 1-3/8" Magnetic Drill

Makita HB350 1-3/8" Magnetic Drill

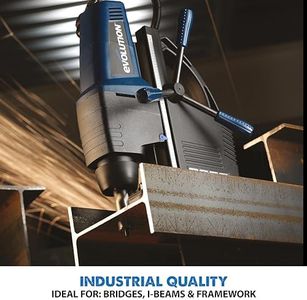

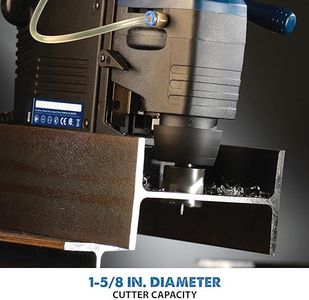

Evolution Power Tools EVOMAG42 1 5/8" Diameter x 2" Depth Magnetic Drilling System

Evolution Power Tools EVOMAG42 1 5/8" Diameter x 2" Depth Magnetic Drilling System

Hougen HMD905 115-Volt Magnetic Drill with Coolant Bottle and 2 Speed

Hougen HMD905 115-Volt Magnetic Drill with Coolant Bottle and 2 Speed

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.