10 Best Ingersoll Rand Impact Wrenches 2025 in the United States

Winner

Ingersoll Rand 2235PTiMAX, Industial Pin Type, 1/2-Inch Pneumatic Impact Wrench, 930 ft-lbs Torque

The Ingersoll Rand 2235PTiMAX is a robust pneumatic impact wrench designed for industrial use, boasting significant torque of 930 ft-lbs reverse and an impressive 1,350 ft-lbs nut-busting torque, making it capable of handling tough bolts effortlessly. Its 1/2-inch drive size is standard for a wide range of applications, enhancing its versatility for different tasks. The pneumatic power source ensures reliable performance for demanding jobs, eliminating concerns about battery life and enabling continuous operation.

Most important from

4703 reviews

Ingersoll Rand W9691-K4E W9000 Series 20-Volt 1-Inch Cordless Impact Wrench Kit with Charger and 6-Inch Extended Anvil

The Ingersoll Rand W9691-K4E W9000 Series impact wrench offers impressive torque, capable of delivering up to 3,000 ft-lbs and 2,200 ft-lbs of tightening torque, making it suitable for heavy-duty applications. Its 1-inch drive size and 6-inch extended anvil facilitate reaching deeper bolts, which is particularly useful for industrial and automotive tasks.

Most important from

181 reviews

Ingersoll Rand 2235TiMAX 1/2-Inch-Drive Air Impact Wrench with Up to 1,350 Foot-Pounds Torque Output

The Ingersoll Rand 2235TiMAX 1/2-Inch-Drive Air Impact Wrench boasts impressive torque capabilities, delivering up to 1,350 foot-pounds of nut-busting power. This makes it ideal for heavy-duty tasks like assembly, disassembly, suspension work, and industrial equipment repair. The wrench is lightweight at just 4.6 pounds, ensuring minimal hand fatigue and comfortable use over extended periods.

Most important from

4703 reviews

Top 10 Best Ingersoll Rand Impact Wrenches 2025 in the United States

Winner

Ingersoll Rand 2235PTiMAX, Industial Pin Type, 1/2-Inch Pneumatic Impact Wrench, 930 ft-lbs Torque

Ingersoll Rand 2235PTiMAX, Industial Pin Type, 1/2-Inch Pneumatic Impact Wrench, 930 ft-lbs Torque

Chosen by 1442 this week

Ingersoll Rand W9691-K4E W9000 Series 20-Volt 1-Inch Cordless Impact Wrench Kit with Charger and 6-Inch Extended Anvil

Ingersoll Rand W9691-K4E W9000 Series 20-Volt 1-Inch Cordless Impact Wrench Kit with Charger and 6-Inch Extended Anvil

Ingersoll Rand 2235TiMAX 1/2-Inch-Drive Air Impact Wrench with Up to 1,350 Foot-Pounds Torque Output

Ingersoll Rand 2235TiMAX 1/2-Inch-Drive Air Impact Wrench with Up to 1,350 Foot-Pounds Torque Output

Ingersoll Rand 2146Q1MAX 3/4-Inch-Drive Air Impact Wrench with Quiet Pistol-Grip Design and 2,000-Foot-Pounds Torque

Ingersoll Rand 2146Q1MAX 3/4-Inch-Drive Air Impact Wrench with Quiet Pistol-Grip Design and 2,000-Foot-Pounds Torque

Ingersoll Rand 2850MAX-6 1-Inch 5,500 rpm Impact Wrench with 6-Inch Anvil Extension

Ingersoll Rand 2850MAX-6 1-Inch 5,500 rpm Impact Wrench with 6-Inch Anvil Extension

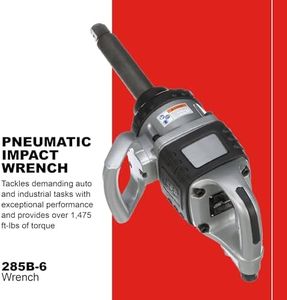

Ingersoll Rand 285B-6 1-Inch Cordless Pneumatic Impact Wrench with 6-Inch Extended Anvil and 2 Handles

Ingersoll Rand 285B-6 1-Inch Cordless Pneumatic Impact Wrench with 6-Inch Extended Anvil and 2 Handles

Ingersoll Rand W7152-K22 20V High-Torque 1/2" Cordless Impact Wrench Kit, 1,500 ft-lbs Torque, 2 Batteries and Charger

Ingersoll Rand W7152-K22 20V High-Torque 1/2" Cordless Impact Wrench Kit, 1,500 ft-lbs Torque, 2 Batteries and Charger

Ingersoll Rand W8591-K2 1" 20V Cordless Impact Wrench 2 Battery Kit, 2000 ft-lb Torque, 6" Extended Anvil, Friction Ring Thru-hole, Pistol

Ingersoll Rand W8591-K2 1" 20V Cordless Impact Wrench 2 Battery Kit, 2000 ft-lb Torque, 6" Extended Anvil, Friction Ring Thru-hole, Pistol

Ingersoll Rand Ingersoll-Rand 280-6 Super Duty 1" Pneumatic Impact Wrench

Ingersoll Rand Ingersoll-Rand 280-6 Super Duty 1" Pneumatic Impact Wrench

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.