10 Best Flux Core Wire Welder 2025 in the United States

Winner

YESWELDER 135Amp MIG Welder,110V Flux Core Welder Flux Core MIG/Lift TIG/Stick 3-in-1 Large LED Digital Display Welding Machine IGBT Inverter Welder FLUX-135PRO

The YESWELDER 135Amp MIG Welder is a versatile and portable option for those in need of a reliable flux-core wire welder. With an amperage output of up to 135 amps, it can effectively weld mild steel plates up to 2/5 inches thick, making it suitable for a range of welding projects. The unit supports three processes: gasless MIG, stick, and Lift TIG, which gives users flexibility depending on their welding needs. If you choose to use TIG, an additional torch is required, which could be an added expense for some.

Most important from

1956 reviews

YESWELDER 185A MIG Welder, Flux Core MIG/Gas MIG/Spool Gun MIG/Lift TIG/Stick 5 in 1 Multi-process Aluminum Welding Machine, LED Digital Display Synergic Control 110V/220V Dual Voltage MIG-185DS PRO

The YESWELDER 185A MIG Welder is a versatile 5-in-1 machine that caters to a range of welding processes including flux core MIG, gas MIG, spool gun MIG, lift TIG, and stick welding. This flexibility is a major strength, making it suitable for both beginners and experienced welders looking to tackle various projects. The synergic control feature, which automatically adjusts voltage based on wire feed speed, enhances ease of use, particularly for those new to welding. Additionally, the advanced digital display offers clear visibility, aiding in precision and efficiency during operation.

Most important from

63 reviews

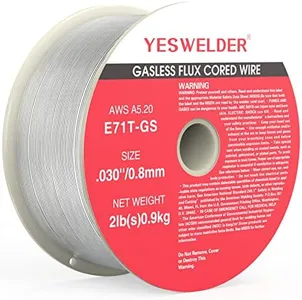

YESWELDER Flux Core Gasless Mig Wire, Mild Steel E71TGS .030-Diameter, 2-Pound Strong ABS Plastic Spool

The YESWELDER Flux Core Gasless Mig Wire is designed for welding mild steel and stands out due to its gasless operation, which makes it convenient for outdoor use, especially in windy conditions. It has a smooth arc action, high feedability, and is easy to weld with, which should appeal to both beginners and experienced welders. The low spatter and easy slag removal contribute to a cleaner and more efficient welding process.

Top 10 Best Flux Core Wire Welder 2025 in the United States

Winner

YESWELDER 135Amp MIG Welder,110V Flux Core Welder Flux Core MIG/Lift TIG/Stick 3-in-1 Large LED Digital Display Welding Machine IGBT Inverter Welder FLUX-135PRO

YESWELDER 135Amp MIG Welder,110V Flux Core Welder Flux Core MIG/Lift TIG/Stick 3-in-1 Large LED Digital Display Welding Machine IGBT Inverter Welder FLUX-135PRO

Chosen by 1311 this week

YESWELDER 185A MIG Welder, Flux Core MIG/Gas MIG/Spool Gun MIG/Lift TIG/Stick 5 in 1 Multi-process Aluminum Welding Machine, LED Digital Display Synergic Control 110V/220V Dual Voltage MIG-185DS PRO

YESWELDER 185A MIG Welder, Flux Core MIG/Gas MIG/Spool Gun MIG/Lift TIG/Stick 5 in 1 Multi-process Aluminum Welding Machine, LED Digital Display Synergic Control 110V/220V Dual Voltage MIG-185DS PRO

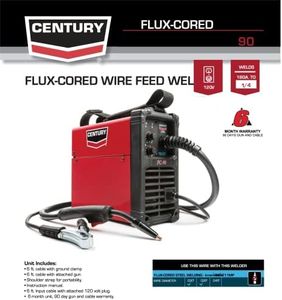

Lincoln Electric 90i FC Flux Core Wire Feed Weld-PAK Welder, 120V Welding Machine, Portable w/Shoulder Strap, Protective Metal Case, Best for Small Jobs, K5255-1

Lincoln Electric 90i FC Flux Core Wire Feed Weld-PAK Welder, 120V Welding Machine, Portable w/Shoulder Strap, Protective Metal Case, Best for Small Jobs, K5255-1

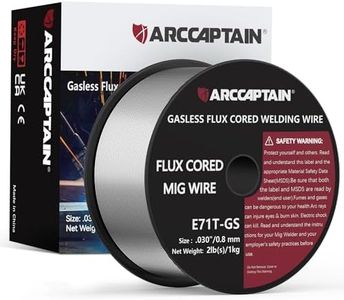

ARCCAPTAIN Flux Core Welding Wire .030, E71T-GS Mig Welding Wire 2-Pound Spool Gasless Mild Carbon Steel Compatible With Lincoln Miller Forney Harbor Welder

ARCCAPTAIN Flux Core Welding Wire .030, E71T-GS Mig Welding Wire 2-Pound Spool Gasless Mild Carbon Steel Compatible With Lincoln Miller Forney Harbor Welder

Lincoln Electric FC90 Flux-Cored Wire Feed Welder – Portable 120V Inverter Welder with Extra-Large Gloves and 1 lb. Spool of 0.035 Flux Core Wire

Lincoln Electric FC90 Flux-Cored Wire Feed Welder – Portable 120V Inverter Welder with Extra-Large Gloves and 1 lb. Spool of 0.035 Flux Core Wire

FORNEY Easy Weld 140 Amp 120-Volt Flux-Cored Wire Feed Welder (No Gas Needed)

FORNEY Easy Weld 140 Amp 120-Volt Flux-Cored Wire Feed Welder (No Gas Needed)

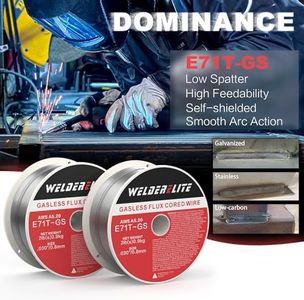

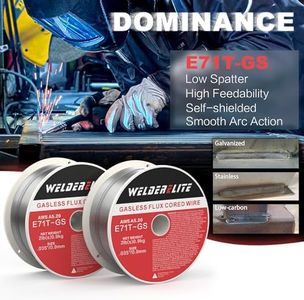

WelderElite 2-Pack 0.030" Gasless Flux Core Wire, 2lb Each, Perfect for MIG Welding Galvanized, Stainless & Mild Steel Projects, E71T-GS

WelderElite 2-Pack 0.030" Gasless Flux Core Wire, 2lb Each, Perfect for MIG Welding Galvanized, Stainless & Mild Steel Projects, E71T-GS

ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound

ARCCAPTAIN Stainless Steel Flux Cored Wire E308LFC-O .030-Diameter MIG Welding Wire Stainless Steel Wire with Low Splatter Compatible With Lincoln Miller Forney Harbor MIG Welder 2-Pound

Recommended lists

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.