10 Best Desoldering Stations 2025 in the United States

YIHUA 853D 2A USB SMD Hot Air Rework Soldering Iron Station, DC Power Supply 0-15V 0-2A with 5V USB Charging Port and 35 Volt DC Voltage Test Meter

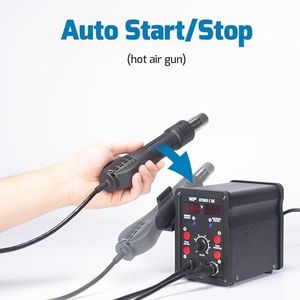

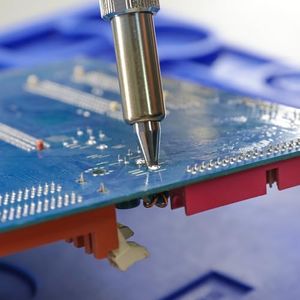

The YIHUA 853D 2A USB is a versatile tool combining a soldering iron station, hot air rework station, and DC power supply in one compact package. For those needing a desoldering station, it offers reasonable temperature control with a wide adjustable range from about 392°F to 896°F, and precise temperature stabilization which helps maintain consistent heat during work. The hot air station includes adjustable airflow up to 120L/min, useful for various component sizes, and comes with four different nozzle sizes to help target specific areas, improving desoldering accuracy.

Most important from

1767 reviews

Top 10 Best Desoldering Stations 2025 in the United States

Winner

YIHUA 853D 2A USB SMD Hot Air Rework Soldering Iron Station, DC Power Supply 0-15V 0-2A with 5V USB Charging Port and 35 Volt DC Voltage Test Meter

YIHUA 853D 2A USB SMD Hot Air Rework Soldering Iron Station, DC Power Supply 0-15V 0-2A with 5V USB Charging Port and 35 Volt DC Voltage Test Meter

Hakko FR-301 - Portable Desoldering Tool

Hakko FR-301 - Portable Desoldering Tool

YIHUA 948-II 4 in 1 Hot Air Rework Soldering Iron and Desoldering Suction Tin Gun Station with Suction Pick Up Pen °F /°C

YIHUA 948-II 4 in 1 Hot Air Rework Soldering Iron and Desoldering Suction Tin Gun Station with Suction Pick Up Pen °F /°C

Weller WT2021MS 2-Channel Digital Soldering Station, 150 W, with 40 W Microsoldering Iron & 80 W Micro Desoldering Tweezers

Weller WT2021MS 2-Channel Digital Soldering Station, 150 W, with 40 W Microsoldering Iron & 80 W Micro Desoldering Tweezers

Recommended lists

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.