10 Best Cnc Wood Routers 2025 in the United States

Winner

FoxAlien CNC Router Machine XE-PRO with Ball Screws, 400W Spindle 3-Axis Engraving Milling Machine for Wood Aluminum Cutting Upgradable to Linear Rails

The FoxAlien CNC Router Machine XE-PRO is a solid choice for those looking to dive into CNC woodworking or metal cutting. Its standout features include NEMA23 closed-loop stepper motors that enhance speed and reduce noise, making the machine run smoothly at a maximum speed of 5000mm/min. The 400W spindle power is adequate for most home projects, allowing you to work on wood and aluminum effectively. Precision is a highlight, thanks to the 1204 ball screws that maintain accuracy during operation, along with robust dual linear rails improving rigidity on the Z-axis.

Most important from

53 reviews

FoxAlien Masuter Pro CNC Router Machine, Upgraded 3-Axis Engraving All-Metal Milling Machine for Wood Acrylic MDF Nylon Carving Cutting

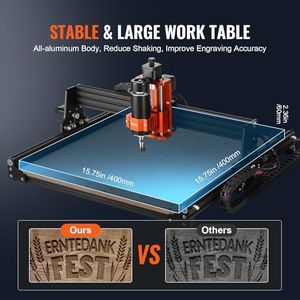

The FoxAlien Masuter Pro CNC Router Machine is an all-aluminum machine designed for precision wood, acrylic, MDF, and nylon carving and cutting. It boasts a large active work area of 15.75” x 15.75” x 2.36” (400 x 400 x 60mm), which is ample for most woodworking projects. The structure is notably sturdy due to the use of linear rails on the Z-axis instead of traditional rods, enhancing stability and accuracy. This makes it a reliable choice for detailed engravings and cuts.

Most important from

471 reviews

Genmitsu CNC Router Machine PROVerXL 4030 for Wood Metal Acrylic MDF Carving Arts Crafts DIY Design, 3 Axis Milling Cutting Engraving Machine, Working Area 400 x 300 x 110mm (15.7''x11.8''x4.3'')

The Genmitsu CNC Router Machine PROVerXL 4030 is a versatile tool designed for woodworking, metal, acrylic, and MDF projects. It boasts a spacious work area of 400 x 300 x 110mm, making it suitable for a variety of carving and engraving tasks. The machine is easy to set up thanks to the pre-assembled XYZ axis and wiring, which means you can start your projects sooner with less hassle. This is especially beneficial for users who may not be very experienced with assembling such machines.

Most important from

500 reviews

Top 10 Best Cnc Wood Routers 2025 in the United States

Winner

FoxAlien CNC Router Machine XE-PRO with Ball Screws, 400W Spindle 3-Axis Engraving Milling Machine for Wood Aluminum Cutting Upgradable to Linear Rails

FoxAlien CNC Router Machine XE-PRO with Ball Screws, 400W Spindle 3-Axis Engraving Milling Machine for Wood Aluminum Cutting Upgradable to Linear Rails

Chosen by 1224 this week

FoxAlien Masuter Pro CNC Router Machine, Upgraded 3-Axis Engraving All-Metal Milling Machine for Wood Acrylic MDF Nylon Carving Cutting

FoxAlien Masuter Pro CNC Router Machine, Upgraded 3-Axis Engraving All-Metal Milling Machine for Wood Acrylic MDF Nylon Carving Cutting

Genmitsu CNC Router Machine PROVerXL 4030 for Wood Metal Acrylic MDF Carving Arts Crafts DIY Design, 3 Axis Milling Cutting Engraving Machine, Working Area 400 x 300 x 110mm (15.7''x11.8''x4.3'')

Genmitsu CNC Router Machine PROVerXL 4030 for Wood Metal Acrylic MDF Carving Arts Crafts DIY Design, 3 Axis Milling Cutting Engraving Machine, Working Area 400 x 300 x 110mm (15.7''x11.8''x4.3'')

Genmitsu CNC Router Machine 4040-PRO for Metal Acrylic Cutting Milling, GRBL Control, Lead Screw Driven, 3 Axis Engraving, Working Area 15.7” x 15.7” x 3.1”

Genmitsu CNC Router Machine 4040-PRO for Metal Acrylic Cutting Milling, GRBL Control, Lead Screw Driven, 3 Axis Engraving, Working Area 15.7” x 15.7” x 3.1”

FoxAlien Masuter 3S CNC Router Machine with NEMA 23 Closed-Loop Stepper Motor, 400W Spindle 3 Axis Engraving Milling Machine for Wood Acrylic Aluminum Carving Cutting

FoxAlien Masuter 3S CNC Router Machine with NEMA 23 Closed-Loop Stepper Motor, 400W Spindle 3 Axis Engraving Milling Machine for Wood Acrylic Aluminum Carving Cutting

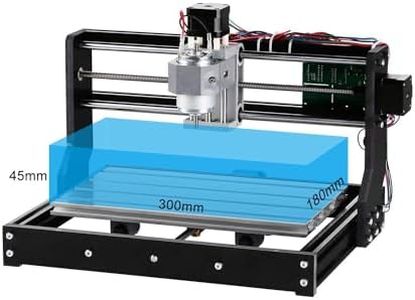

Genmitsu CNC 3018-PRO Router Kit GRBL Control 3 Axis Plastic Acrylic PCB PVC Wood Carving Milling Engraving Machine with Offline Controller, XYZ Working Area 300 x 180 x 45mm

Genmitsu CNC 3018-PRO Router Kit GRBL Control 3 Axis Plastic Acrylic PCB PVC Wood Carving Milling Engraving Machine with Offline Controller, XYZ Working Area 300 x 180 x 45mm

Genmitsu CNC Machine PROVerXL 6050 Plus for Metal Wood Acrylic MDF Carving, GRBL Control, 3 Axis Milling CNC Router Machine, Hybrid Table, Working Area 600 x 500 x 115mm (23.62" x 19.69" x 4.53")

Genmitsu CNC Machine PROVerXL 6050 Plus for Metal Wood Acrylic MDF Carving, GRBL Control, 3 Axis Milling CNC Router Machine, Hybrid Table, Working Area 600 x 500 x 115mm (23.62" x 19.69" x 4.53")

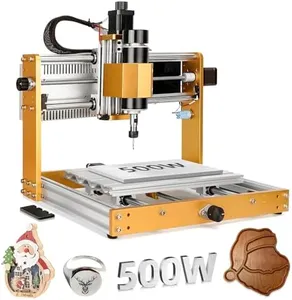

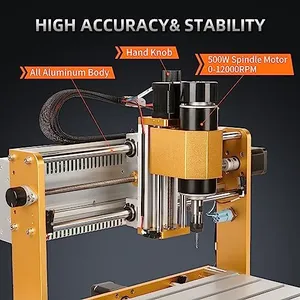

LUNYEE 3018 PRO MAX CNC Machine 500W All-Metal CNC Router Machine 3 Axis Limit Switches & Emergency-Stop with GRBL Offline Control for Cutting Wood Acrylic MDF Plastic, Working Area: 300 x 180 x 80mm

LUNYEE 3018 PRO MAX CNC Machine 500W All-Metal CNC Router Machine 3 Axis Limit Switches & Emergency-Stop with GRBL Offline Control for Cutting Wood Acrylic MDF Plastic, Working Area: 300 x 180 x 80mm

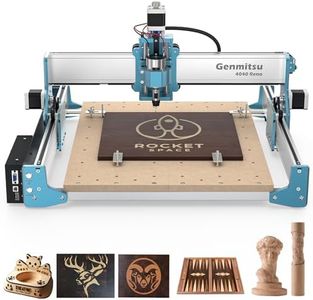

Genmitsu 4040 Reno CNC Router Milling Machine for Woodworking Acrylic Cutting, Belt Driven, Quieter Movement, Wood Metal Carving Cutter Engraver, Working Area 15.75′′ x 15.75′′ x 3′′

Genmitsu 4040 Reno CNC Router Milling Machine for Woodworking Acrylic Cutting, Belt Driven, Quieter Movement, Wood Metal Carving Cutter Engraver, Working Area 15.75′′ x 15.75′′ x 3′′

VEVOR CNC Router Machine, 300W, 3 Axis GRBL Control Wood Engraving Carving Milling Machine Kit, 400 x 400 x 75 mm / 15.7 x 15.7 x 2.95 in Working Area 12000 RPM for Wood Acrylic MDF PVC Plastic Foam

VEVOR CNC Router Machine, 300W, 3 Axis GRBL Control Wood Engraving Carving Milling Machine Kit, 400 x 400 x 75 mm / 15.7 x 15.7 x 2.95 in Working Area 12000 RPM for Wood Acrylic MDF PVC Plastic Foam

Recommended lists

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

![Garvee X-Axis Power Feed for Power Milling Machine, [450 LB Torque]110V, 0-200PRM Adjustable Rotate Speed for Bridgeport and Similar Knee Type Milling Machines](https://images-proxy.bestreviews.guide/_GdzehAT4hZ1w-_DZdegJO-rlDc=/0x300/https://m.media-amazon.com/images/I/41N1fxmEFDL._AC_CX679_.jpg)