9 Best Circular Saw Blade For Laminate 2025 in the United States

Winner

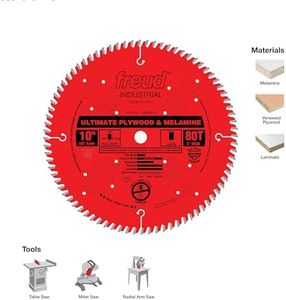

Freud LU80R010: 10" Ultimate Plywood & Melamine Blade

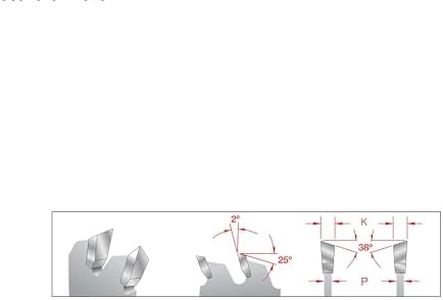

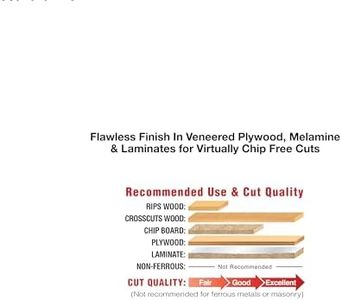

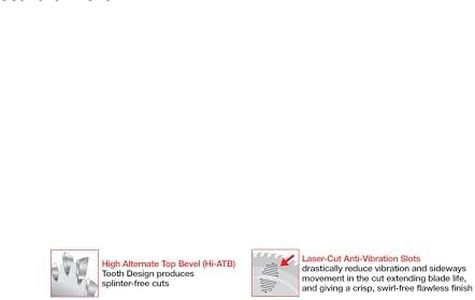

The Freud LU80R010 is a high-quality circular saw blade designed specifically for cutting plywood and melamine, which makes it suitable for laminate materials as well. With a 10-inch diameter and 80 teeth, this blade offers a fine, splinter-free finish thanks to its High Alternate Top Bevel (Hi-ATB) tooth design. The kerf width of .126 inches is reasonably thin, allowing for precise cuts without excessive material waste. The hook angle of 2 degrees helps maintain control while cutting, reducing the risk of kickback and ensuring smoother operation.

Most important from

467 reviews

Freud LU97R010: 10" Double Sided Laminate/Melamine Blade

The Freud LU97R010 is a 10-inch circular saw blade designed for cutting double-sided laminate and melamine materials. With 80 teeth and a Triple Chip Grind (TCG) tooth design, this blade is built to last and provide precise cuts. The -3° hook angle and .126-inch kerf width ensure smooth, clean cuts with minimal material splintering, making it suitable for professional use.

Most important from

194 reviews

PCD Laminate Flooring Blade

The PCD Laminate Flooring Blade by Freud is designed specifically for cutting laminate flooring and is compatible with chop saws. With a blade diameter of 12 inches, it is substantial enough for various laminate flooring projects. The blade has a very fine grit type and is made from durable diamond material, ensuring a long lifespan and precise cuts. It is noted for its 'Super-Abrasive' construction which is ideal for handling tough laminate surfaces.

Most important from

141 reviews

Top 9 Best Circular Saw Blade For Laminate 2025 in the United States

Winner

9.8 score

Freud LU80R010: 10" Ultimate Plywood & Melamine Blade

Freud LU80R010: 10" Ultimate Plywood & Melamine Blade

Chosen by 1223 this week

Freud LU97R010: 10" Double Sided Laminate/Melamine Blade

Freud LU97R010: 10" Double Sided Laminate/Melamine Blade

PCD Laminate Flooring Blade

PCD Laminate Flooring Blade

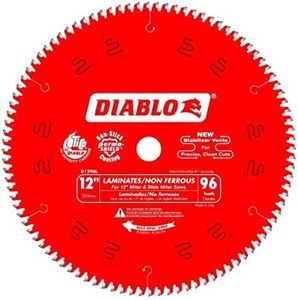

Diablo Melamine, Laminate Flooring, and Wood Saw Blade

Diablo Melamine, Laminate Flooring, and Wood Saw Blade

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.