10 Best Circular Saw Blades 2025 in the United States

Winner

SKIL 7-1/4 in. 24-Tooth Carbide Framing Circular Saw Blade, 10-Pack-75724-10

The SKIL 7-1/4 inch circular saw blade with 24 carbide teeth is designed mainly for framing and general wood cutting tasks. Its tooth configuration uses alternating top bevel (ATB) teeth, which helps deliver smoother cuts in wood and reduces chip-out. The blade is made with titanium carbide teeth, making it quite durable and able to maintain sharpness over time. A clear anti-stick coating lowers friction and heat, which not only helps with cleaner cuts but also protects the blade from rust and wear.

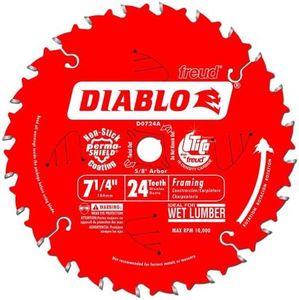

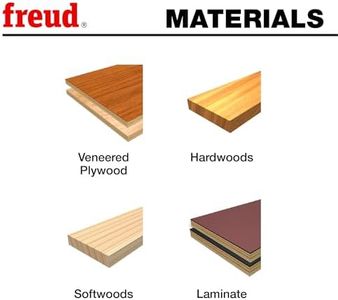

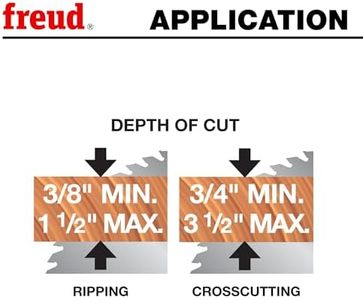

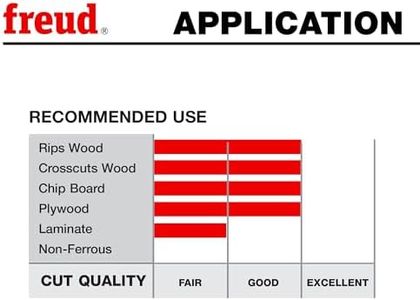

Freud D0724A Diablo 7-1/4-inch 24T ATB Thin Kerf Framing Saw Blades, 10-Pack

The Diablo D0724A 7-1/4" 24T Circular Saw Framing Blade is a dependable choice for those working with engineered wood. One of its main strengths is its construction material; the blade is made from carbide, which is known for its durability and ability to maintain sharpness over time. The kerf width of 0.059 inches allows for precise cuts with minimal material wastage.

Freud Diablo D0648CFX 6-1/2" x 48 Teeth Demon Ferrous Cutting Circular Saw Blade

The Diablo Steel Demon Cermet II is a 6-1/2 inch circular saw blade designed specifically for cutting metals and stainless steel. It has 48 tooth count with a triple-chip grind (TCG) configuration, which is great for smoother, cleaner cuts on hard materials. The .061 inch kerf width strikes a good balance between material removal and reduced waste, while its carbide teeth enhanced with advanced cermet (ceramic and metallic) offer excellent durability—lasting up to 25 times longer than standard blades. This means fewer blade changes and less downtime.

Most important from

4505 reviews

Top 10 Best Circular Saw Blades 2025 in the United States

Winner

SKIL 7-1/4 in. 24-Tooth Carbide Framing Circular Saw Blade, 10-Pack-75724-10

SKIL 7-1/4 in. 24-Tooth Carbide Framing Circular Saw Blade, 10-Pack-75724-10

Chosen by 1392 this week

Freud D0724A Diablo 7-1/4-inch 24T ATB Thin Kerf Framing Saw Blades, 10-Pack

Freud D0724A Diablo 7-1/4-inch 24T ATB Thin Kerf Framing Saw Blades, 10-Pack

Freud Diablo D0648CFX 6-1/2" x 48 Teeth Demon Ferrous Cutting Circular Saw Blade

Freud Diablo D0648CFX 6-1/2" x 48 Teeth Demon Ferrous Cutting Circular Saw Blade

Freud D0624A Diablo 6-1/2-inch 24T ATB Perma-Shield Framing Saw Blades, 10-Pack

Freud D0624A Diablo 6-1/2-inch 24T ATB Perma-Shield Framing Saw Blades, 10-Pack

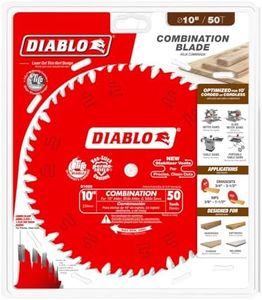

Freud Combination Saw Blade with Premium Tico Hi-Density Carbide Combination Blend for Maximum Performance - 10" Diameter, 50 Teeth, Comb Grind - LU84R011

Freud Combination Saw Blade with Premium Tico Hi-Density Carbide Combination Blend for Maximum Performance - 10" Diameter, 50 Teeth, Comb Grind - LU84R011

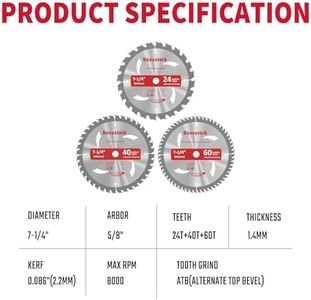

3 Pack 7 1/4 Circular Saw Blade 24T&40T&60T Combo, TCT ATB 24T Framing, 40T Ripping & Crosscutting, 60T Finish Saw Blade for Various Wood Cutting, 5/8" Arbor, Fit Dewalt Craftsman Ryobi Milwaukee

3 Pack 7 1/4 Circular Saw Blade 24T&40T&60T Combo, TCT ATB 24T Framing, 40T Ripping & Crosscutting, 60T Finish Saw Blade for Various Wood Cutting, 5/8" Arbor, Fit Dewalt Craftsman Ryobi Milwaukee

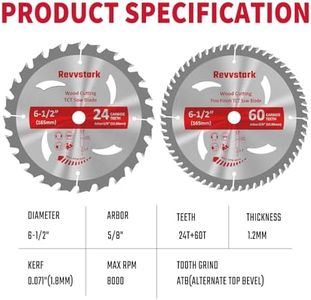

Revvstark Circular Saw Blade 6-1/2" 24T&60T, Carbide Tipped Teeth, TCT Saw Blades for Cutting Various Wood, Plastic and Composite Materials, 5/8" Arbor, Fit Dewalt Craftsman Ryobi Milwaukee

Revvstark Circular Saw Blade 6-1/2" 24T&60T, Carbide Tipped Teeth, TCT Saw Blades for Cutting Various Wood, Plastic and Composite Materials, 5/8" Arbor, Fit Dewalt Craftsman Ryobi Milwaukee

Freud LM75R010: 10" Industrial Thin Kerf Glue Line Ripping Blade, Carbide

Freud LM75R010: 10" Industrial Thin Kerf Glue Line Ripping Blade, Carbide

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.