10 Best Benchtop Jointers 2025 in the United States

Winner

POWERTEC UT1012C 13 Inch Benchtop Thickness Planer, 6 Inch Benchtop Jointer with Flip Top Tool Stand

The POWERTEC UT1012C is a versatile benchtop solution that combines a 6-inch jointer and a 13-inch planer, both mounted on a clever flip-top tool stand with wheels for easy tool switching and workshop mobility. Its 6-inch jointer features a 10-amp motor and a 2-blade cutterhead, capable of removing up to 1/8 inch of material per pass. This makes it suitable for smoothing edges, prepping boards for gluing, and creating precise joints. The jointer's fence and table size provide stable support, which is important for accurate cuts.

Cutech 401120HI-IF 12-Inch Spiral Cutterhead Benchtop Jointer with Cast Iron Tables, 24 TC Inserts, Extra Large 24" x 6" Cast Iron Fence, Additional 8½" Fence Enhancement Brackets, and a 12-amp Motor

The Cutech 401120HI-IF 12-Inch Spiral Cutterhead Benchtop Jointer offers several appealing features for woodworking enthusiasts. One of its key strengths is the 12-inch cutting width, which allows for handling larger pieces of wood. The spiral cutterhead with 24 staggered inserts is designed to give a smoother finish and operate with a low amp draw, which can be beneficial for efficiency.

Cutech 401100HI 10-Inch Spiral Cutterhead Benchtop Jointer with Cast Iron Tables, 20 TC Inserts, Extra Long 24" Aluminum Fence, Additional 7-3/8" Fence Brackets, and a 12-amp Motor

The Cutech 401100HI 10-Inch Spiral Cutterhead Benchtop Jointer is a solid choice for woodworkers looking for a reliable jointer that can handle various tasks. One of its standout features is the spiral cutterhead, which uses 20 staggered inserts to deliver a smooth finish. This design not only enhances the quality of cuts but also contributes to lower amp draw, making it more energy-efficient compared to some competing models. The powerful 12-amp motor is another major plus, providing a significant boost in cutting power that can tackle aggressive cuts with ease. Users who often work with larger or heavier materials will appreciate the extra stability provided by the patented fence enhancement brackets and additional support rod system. These elements help ensure accurate cuts and reduce any wobbling during operation.

Most important from

145 reviews

Top 10 Best Benchtop Jointers 2025 in the United States

Winner

POWERTEC UT1012C 13 Inch Benchtop Thickness Planer, 6 Inch Benchtop Jointer with Flip Top Tool Stand

POWERTEC UT1012C 13 Inch Benchtop Thickness Planer, 6 Inch Benchtop Jointer with Flip Top Tool Stand

Chosen by 1482 this week

Cutech 401120HI-IF 12-Inch Spiral Cutterhead Benchtop Jointer with Cast Iron Tables, 24 TC Inserts, Extra Large 24" x 6" Cast Iron Fence, Additional 8½" Fence Enhancement Brackets, and a 12-amp Motor

Cutech 401120HI-IF 12-Inch Spiral Cutterhead Benchtop Jointer with Cast Iron Tables, 24 TC Inserts, Extra Large 24" x 6" Cast Iron Fence, Additional 8½" Fence Enhancement Brackets, and a 12-amp Motor

Cutech 401100HI 10-Inch Spiral Cutterhead Benchtop Jointer with Cast Iron Tables, 20 TC Inserts, Extra Long 24" Aluminum Fence, Additional 7-3/8" Fence Brackets, and a 12-amp Motor

Cutech 401100HI 10-Inch Spiral Cutterhead Benchtop Jointer with Cast Iron Tables, 20 TC Inserts, Extra Long 24" Aluminum Fence, Additional 7-3/8" Fence Brackets, and a 12-amp Motor

Cutech 40180HI 8-Inch Spiral Cutterhead Benchtop Jointer with Cast Iron Tables, 16 TC Inserts, Extra Long 24" Aluminum Fence, Additional 7-3/8" Fence Brackets, and a 10-amp Motor

Cutech 40180HI 8-Inch Spiral Cutterhead Benchtop Jointer with Cast Iron Tables, 16 TC Inserts, Extra Long 24" Aluminum Fence, Additional 7-3/8" Fence Brackets, and a 10-amp Motor

Cutech 401120HI 12-Inch Spiral Cutterhead Benchtop Jointer with Cast Iron Tables, 24 TC Inserts, Extra Long 24" Aluminum Fence, Additional 7-3/8" Fence Brackets, and a 12-amp Motor

Cutech 401120HI 12-Inch Spiral Cutterhead Benchtop Jointer with Cast Iron Tables, 24 TC Inserts, Extra Long 24" Aluminum Fence, Additional 7-3/8" Fence Brackets, and a 12-amp Motor

WEN 12-Amp 10-Inch Spiral Benchtop Jointer with Extendable Cast-Iron Table (JT1020H)

WEN 12-Amp 10-Inch Spiral Benchtop Jointer with Extendable Cast-Iron Table (JT1020H)

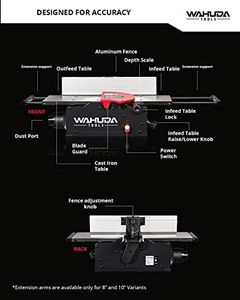

Wahuda Tools Jointer - 10-inch Benchtop Wood Jointer, Spiral Cutterhead Portable Jointer, Cast Iron Tables w/Pull Out Extensions, 4-Sided Carbide Tips & 12amp Motor, Woodworking Tools (50110CC-WHD)

Wahuda Tools Jointer - 10-inch Benchtop Wood Jointer, Spiral Cutterhead Portable Jointer, Cast Iron Tables w/Pull Out Extensions, 4-Sided Carbide Tips & 12amp Motor, Woodworking Tools (50110CC-WHD)

WEN JT630H 10-Amp 6-Inch Spiral Benchtop Jointer

WEN JT630H 10-Amp 6-Inch Spiral Benchtop Jointer

JET BLACK 8-Inch Jointer, Helical Cutterhead, 2 HP, 230V 1Ph (Model JWJ-8HH-BLK)

JET BLACK 8-Inch Jointer, Helical Cutterhead, 2 HP, 230V 1Ph (Model JWJ-8HH-BLK)

Wahuda Tools Jointer - 8-inch Benchtop Wood Jointer, Spiral Cutterhead Portable Jointer, Cast Iron Tables w/Pull Out Extensions, 4-Sided Carbide Tips & 10amp Motor, Woodworking Tools (50180CC-WHD)

Wahuda Tools Jointer - 8-inch Benchtop Wood Jointer, Spiral Cutterhead Portable Jointer, Cast Iron Tables w/Pull Out Extensions, 4-Sided Carbide Tips & 10amp Motor, Woodworking Tools (50180CC-WHD)

Recommended lists

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.