10 Best Saw Horse Brackets 2026 in the United States

Winner

BORA Workhorse Saw horses 2 pack Folding Heavy Duty Legs, Metal Saw horse with 2x4 Bracket Built in Bottle Opener Professional Saw Horse for Woodworking Carpenters Contractors PM-3350T

The Bora Workhorse Sawhorses 2 pack offers a solid solution for woodworking, carpenters, and contractors. These saw horses are made entirely of metal, ensuring durability and long-term use. A standout feature is their impressive weight capacity of 1350 lbs per sawhorse, totaling 2700 lbs for the pair, making them suitable for heavy-duty tasks.

Most important from

962 reviews

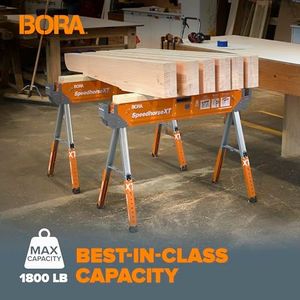

Bora Portamate Speedhorse XT Sawhorse Pair- Two pack, 30-36 inch height adjustable Legs, Metal Top for 2x4, Heavy Duty Pro Bench Saw Horse for Contractors, Carpenters - PM-4550T,Orange

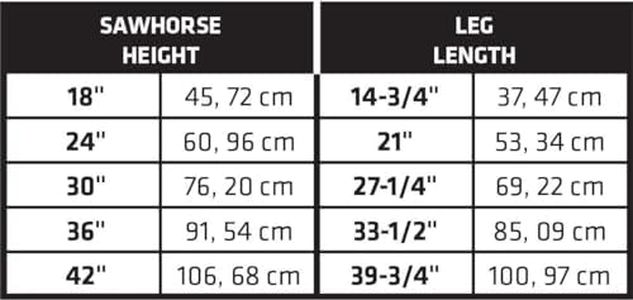

The Bora Portamate Speedhorse XT Sawhorse Pair is a solid choice for contractors and carpenters who need durable and adjustable work supports. Made with a metal top for 2x4s, these sawhorses boast a significant weight capacity of up to 1800 lbs each, making them suitable for heavy-duty projects. The height is adjustable from 30 to 36 inches, with easy slide and lock technology, providing the flexibility needed for various work environments. This feature also allows for individual leg height adjustments, ensuring stability even on uneven ground.

Most important from

1546 reviews

Amazon Basics Rectangular Folding Sawhorse - Set of 2, 900 Pound Capacity, Orange and Grey

The Amazon Basics Rectangular Folding Sawhorse set of 2 is a reliable option for those needing sturdy support for various projects. Crafted from durable materials, it boasts a significant weight capacity of 900 pounds, evenly distributed across both sawhorses, making it suitable for heavy-duty tasks. The design includes locking braces and non-slip feet, which enhance stability and secure anchoring during use.

Most important from

8175 reviews

Top 10 Best Saw Horse Brackets 2026 in the United States

Winner

BORA Workhorse Saw horses 2 pack Folding Heavy Duty Legs, Metal Saw horse with 2x4 Bracket Built in Bottle Opener Professional Saw Horse for Woodworking Carpenters Contractors PM-3350T

BORA Workhorse Saw horses 2 pack Folding Heavy Duty Legs, Metal Saw horse with 2x4 Bracket Built in Bottle Opener Professional Saw Horse for Woodworking Carpenters Contractors PM-3350T

Chosen by 1116 this week

Bora Portamate Speedhorse XT Sawhorse Pair- Two pack, 30-36 inch height adjustable Legs, Metal Top for 2x4, Heavy Duty Pro Bench Saw Horse for Contractors, Carpenters - PM-4550T,Orange

Bora Portamate Speedhorse XT Sawhorse Pair- Two pack, 30-36 inch height adjustable Legs, Metal Top for 2x4, Heavy Duty Pro Bench Saw Horse for Contractors, Carpenters - PM-4550T,Orange

Amazon Basics Rectangular Folding Sawhorse - Set of 2, 900 Pound Capacity, Orange and Grey

Amazon Basics Rectangular Folding Sawhorse - Set of 2, 900 Pound Capacity, Orange and Grey

BORA Workhorse Saw Horses 2 Pack Folding Heavy Duty Sawhorse Pair - Heavy Duty Saw Horse for Contractors Portable Workbench - PM-3330T

BORA Workhorse Saw Horses 2 Pack Folding Heavy Duty Sawhorse Pair - Heavy Duty Saw Horse for Contractors Portable Workbench - PM-3330T

KREG KWS500 Track Horse Tool - Use as Sawhorse, Work Support & Clamping Center Bench Clamp - Tools for Woodworking - Supports 2,200 Lb - Holiday Home Improvement Gifts for Him

KREG KWS500 Track Horse Tool - Use as Sawhorse, Work Support & Clamping Center Bench Clamp - Tools for Woodworking - Supports 2,200 Lb - Holiday Home Improvement Gifts for Him

WORKESS Saw Horses 2 Pack Folding, Heavy Duty Sawhorse Table 2600 Lbs Load Capacity with 2x4 Support Legs, Portable Folding and Fast Open Legs and Easy Grip Handle for Woodworking.

WORKESS Saw Horses 2 Pack Folding, Heavy Duty Sawhorse Table 2600 Lbs Load Capacity with 2x4 Support Legs, Portable Folding and Fast Open Legs and Easy Grip Handle for Woodworking.

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.