10 Best Power Screeds For Concrete 2025 in the United States

Winner

TOMAHAWK Power Screed Concrete Finishing Vibra Tool with 14 ft & 10 ft Boards Bull Float Finisher Set

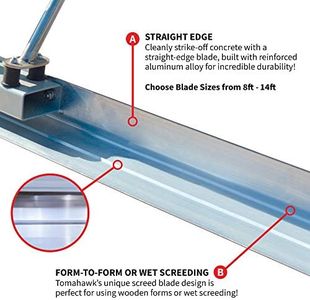

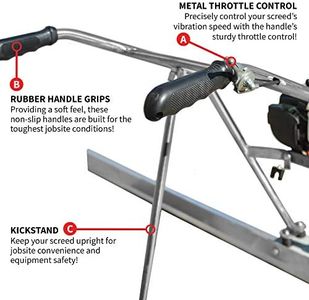

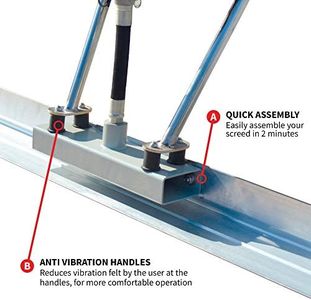

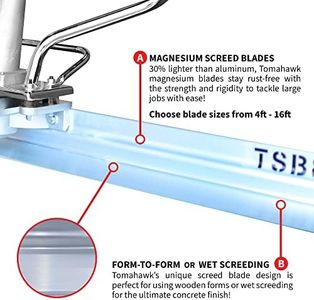

The TOMAHAWK Power Screed for Concrete Finishing is equipped with a robust 37.7cc 4-Stroke Tomahawk gasoline engine, ensuring a consistent vibration of 7000 VPM across the blade. This makes it highly effective in creating uniform finishes on concrete surfaces. The product includes two hardened aluminum boards (14 ft and 10 ft) which are designed for efficient form-to-form or wet screeding. This helps to strike off concrete floors rapidly and with high precision, cutting down labor costs by over 75%.

TOMAHAWK 1.6 HP Honda Gas Vibrating Concrete Power Screed Motor with GX35 Honda Engine

The Tomahawk 1.6 HP Honda Gas Vibrating Concrete Power Screed Motor stands out with its reliable GX35 Honda Engine, known for quality and durability. This engine offers 1.6 horsepower, providing sufficient power to efficiently level up to four times more concrete than traditional methods. The engine's three-year warranty ensures long-term reliability, while the power screed motor is covered with a one-year warranty, demonstrating confidence in the product's durability and performance.

Most important from

48 reviews

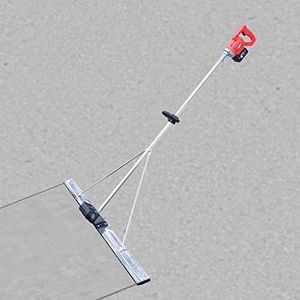

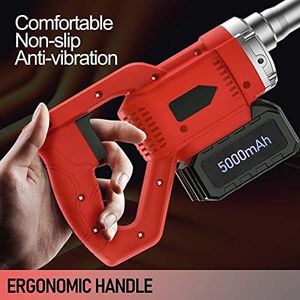

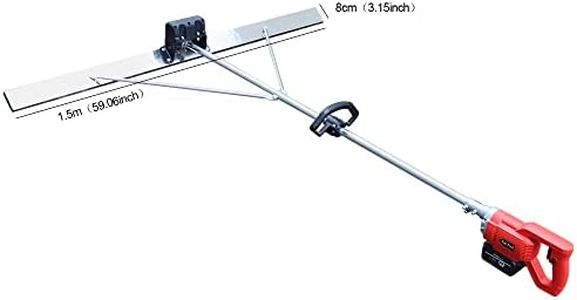

TOMAHAWK 37.7cc Gas Concrete Power Screed Cement Finishing Vibrating Motor with 8ft Aluminum Board Straight Edge Bar Vibra Finisher Set

The TOMAHAWK 37.7cc Gas Concrete Power Screed is designed for efficient concrete finishing with its robust 4-stroke gasoline engine that delivers a powerful 7000 vibrations per minute (VPM). This ensures a uniform vibration across the 8-foot aluminum blade, which is ideal for providing near bull float finishing results on concrete surfaces. One of the key advantages is its efficiency, claiming to work four times faster than traditional methods and significantly reducing labor costs by up to 75%.

Most important from

10 reviews

Top 10 Best Power Screeds For Concrete 2025 in the United States

Winner

9.8 score

TOMAHAWK Power Screed Concrete Finishing Vibra Tool with 14 ft & 10 ft Boards Bull Float Finisher Set

TOMAHAWK Power Screed Concrete Finishing Vibra Tool with 14 ft & 10 ft Boards Bull Float Finisher Set

Chosen by 1104 this week

TOMAHAWK 1.6 HP Honda Gas Vibrating Concrete Power Screed Motor with GX35 Honda Engine

TOMAHAWK 1.6 HP Honda Gas Vibrating Concrete Power Screed Motor with GX35 Honda Engine

TOMAHAWK 37.7cc Gas Concrete Power Screed Cement Finishing Vibrating Motor with 8ft Aluminum Board Straight Edge Bar Vibra Finisher Set

TOMAHAWK 37.7cc Gas Concrete Power Screed Cement Finishing Vibrating Motor with 8ft Aluminum Board Straight Edge Bar Vibra Finisher Set

MBW Power Screed Demon with 6-foot Screed Bar

MBW Power Screed Demon with 6-foot Screed Bar

7.5 score

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.