10 Best Parallel Bar Clamps 2025 in the United States

Winner

JORGENSEN 36-inch Bar Clamps, 90°Cabinet Master Parallel Jaw Bar Clamp Set, 2-pack

The JORGENSEN 36-inch Bar Clamps are designed to handle a wide range of woodworking tasks, from panel glue-ups to cabinet making. With a substantial clamping capacity of 36 inches and a clamping force of up to 1500 lbs., these clamps can secure large and heavy projects effectively. The high-carbon steel bar and heavy-duty steel jaws ensure durability and strength, making these clamps a reliable choice for both hobbyists and professional woodworkers.

Most important from

1072 reviews

Bora 4-Piece Parallel Clamp Set 571550I

The Bora 4-Piece Parallel Clamp Set 571550I is a robust choice for woodworking tasks, offering significant clamping capacity with its 1,100 lbs clamping force. The padded jaws are 3.5 inches wide, providing even pressure without damaging the work material, which is ideal for delicate woodworking projects. The jaw pads remain in place while winding, adding to the precision of your work.

Most important from

457 reviews

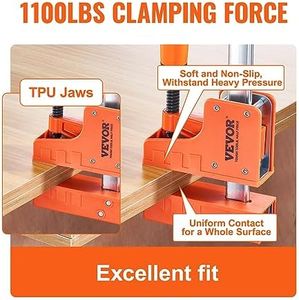

VEVOR Bar Clamps for Woodworking, 2-Pack 50" Parallel Clamp Set, F Clamp with 1100 lbs Load Limit, Even Pressure, High-strength Plastic and Carbon Steel, Wood clamps for Woodworking Metal Working

The VEVOR 2-Pack 50" Parallel Clamp Set is a robust and versatile tool designed for woodworking and metalworking. One of its standout features is the impressive 1100 lbs clamping force, making it suitable for a variety of heavy-duty tasks. The 50-inch jaw opening provides ample space for securing large workpieces, which is ideal for most standard-sized woods and even small metalworking projects.

Top 10 Best Parallel Bar Clamps 2025 in the United States

Winner

JORGENSEN 36-inch Bar Clamps, 90°Cabinet Master Parallel Jaw Bar Clamp Set, 2-pack

JORGENSEN 36-inch Bar Clamps, 90°Cabinet Master Parallel Jaw Bar Clamp Set, 2-pack

Chosen by 1160 this week

Bora 4-Piece Parallel Clamp Set 571550I

Bora 4-Piece Parallel Clamp Set 571550I

VEVOR Bar Clamps for Woodworking, 2-Pack 50" Parallel Clamp Set, F Clamp with 1100 lbs Load Limit, Even Pressure, High-strength Plastic and Carbon Steel, Wood clamps for Woodworking Metal Working

VEVOR Bar Clamps for Woodworking, 2-Pack 50" Parallel Clamp Set, F Clamp with 1100 lbs Load Limit, Even Pressure, High-strength Plastic and Carbon Steel, Wood clamps for Woodworking Metal Working

Bora 50" Parallel Clamp Set, 2 Pack of Woodworking Clamps with Rock-Solid, Even Pressure, 571150T

Bora 50" Parallel Clamp Set, 2 Pack of Woodworking Clamps with Rock-Solid, Even Pressure, 571150T

BESSEY KREX2450 K Body REVO Clamp Kit, 2 x 24 In., 2 x 50 In. and 2 KBX20 Extenders - 1700 lbs Nominal Clamping Force. Spreader, and Woodworking Accessories - Clamps and Tools for Cabinetry

BESSEY KREX2450 K Body REVO Clamp Kit, 2 x 24 In., 2 x 50 In. and 2 KBX20 Extenders - 1700 lbs Nominal Clamping Force. Spreader, and Woodworking Accessories - Clamps and Tools for Cabinetry

JET Parallel Clamp Framing Kit (70411)

JET Parallel Clamp Framing Kit (70411)

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.