10 Best Mug Heat Presses For Sublimation 2025 in the United States

Winner

HTVRONT Auto Tumbler Heat Press Machine - Mug Heat Press Heat Up Fast & Even, Professional Tumbler Press High-Security for 2.95"-3.18" Sublimation Tumblers, Cups, Glasses and Mugs, White

The HTVRONT Auto Tumbler Heat Press is designed to make sublimation printing on mugs and tumblers easier and more efficient. It has a good temperature range that goes up to 390°F, which covers most sublimation needs. One of its best features is the automatic pressure adjustment based on your tumbler size, so you don’t have to manually tweak it, saving time and reducing guesswork. This makes it particularly helpful if you want consistent and professional results. It fits a wide range of mug sizes, from 2.95 inches up to 3.18 inches in diameter, and can handle volumes between 10 to 30 ounces, covering most standard tumblers and cups.

Most important from

1587 reviews

VEVOR 8 in 1 Heat Press Machine 15x15 Inch, 360° Swing Away Shirt Press Machine - Digital Professional Heat Transfer Tshirt Press Machine, Sublimation Heat Press for T Shirts Hat Cap Mug Plate Blue

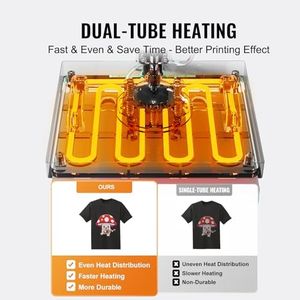

The VEVOR 8 in 1 Heat Press Machine offers extensive versatility with its 15x15 inch heating platen and 360° swing-away design, making it suitable for a wide range of items, including T-shirts, mugs, caps, and plates. The digital control and dual-screen display are user-friendly, allowing precise temperature adjustments with a simple interface. The dual-tube heating technology ensures even heat distribution, enhancing the quality of each transfer.

Most important from

2014 reviews

Cricut Mug Press + 4 Blank Mugs (12oz each)

The Cricut Mug Press, bundled with four 12oz blank mugs, is an accessible and user-friendly option for creating custom mug designs. It utilizes a one-touch setting to simplify the process, allowing you to turn mug blanks ranging from 11 oz to 16 oz into unique, dishwasher-safe creations. This press achieves consistent results due to its patent-pending heat plate with zone heating.

Most important from

4454 reviews

Top 10 Best Mug Heat Presses For Sublimation 2025 in the United States

Winner

HTVRONT Auto Tumbler Heat Press Machine - Mug Heat Press Heat Up Fast & Even, Professional Tumbler Press High-Security for 2.95"-3.18" Sublimation Tumblers, Cups, Glasses and Mugs, White

HTVRONT Auto Tumbler Heat Press Machine - Mug Heat Press Heat Up Fast & Even, Professional Tumbler Press High-Security for 2.95"-3.18" Sublimation Tumblers, Cups, Glasses and Mugs, White

Chosen by 1490 this week

VEVOR 8 in 1 Heat Press Machine 15x15 Inch, 360° Swing Away Shirt Press Machine - Digital Professional Heat Transfer Tshirt Press Machine, Sublimation Heat Press for T Shirts Hat Cap Mug Plate Blue

VEVOR 8 in 1 Heat Press Machine 15x15 Inch, 360° Swing Away Shirt Press Machine - Digital Professional Heat Transfer Tshirt Press Machine, Sublimation Heat Press for T Shirts Hat Cap Mug Plate Blue

Cricut Mug Press + 4 Blank Mugs (12oz each)

Cricut Mug Press + 4 Blank Mugs (12oz each)

VEVOR 15x15 Heat Press Machine 8 in 1 Combo with 30 OZ Tumbler Press & Hat Press, Slide Out Heat Press Sublimation Machine for T-Shirts, Hats Caps Tumblers Glass Cans Mugs, and Plates (Light Green)

VEVOR 15x15 Heat Press Machine 8 in 1 Combo with 30 OZ Tumbler Press & Hat Press, Slide Out Heat Press Sublimation Machine for T-Shirts, Hats Caps Tumblers Glass Cans Mugs, and Plates (Light Green)

BetterSub 3in1 40 OZ Tumbler Mug Heat Press Machine 30 OZ 20 OZ 16 OZ Sublimation Straight Skinny Tumbler Mug,11 OZ 15 OZ 16 OZ Sublimation Mug Heat Transfer Teal

BetterSub 3in1 40 OZ Tumbler Mug Heat Press Machine 30 OZ 20 OZ 16 OZ Sublimation Straight Skinny Tumbler Mug,11 OZ 15 OZ 16 OZ Sublimation Mug Heat Transfer Teal

VEVOR Heat Press Machine 8 in 1 Combo Heat Press 15x15 Inch Heat Transfer Machine 360-Degree Swing Away Digital Tshirt Press Multifunction Heat Transfer Sublimation for T Shirts Mugs Hats Plates Caps

VEVOR Heat Press Machine 8 in 1 Combo Heat Press 15x15 Inch Heat Transfer Machine 360-Degree Swing Away Digital Tshirt Press Multifunction Heat Transfer Sublimation for T Shirts Mugs Hats Plates Caps

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.