10 Best Miter Saws For Metal Cutting 2025 in the United States

Winner

Metabo HPT 10-Inch Compound Miter Saw, 15-Amp Power Saw with Large 10-Inch Table, Precision Miter Angles, Single Bevel 0-45°, 24T TCT Blade, Positive Stops, Lightweight Design, C10FCGS

The Metabo HPT 10-Inch Compound Miter Saw is powered by a robust 15-Amp motor that delivers up to 5,000 RPM, making it capable of handling tough cuts, although its primary recommendation is for woodworking rather than metal cutting. The blade provided is high-speed steel with 24 teeth, which is generally suitable for woodworking but may require an upgrade to a carbide-tipped blade for better efficiency when cutting metal.

Most important from

11363 reviews

DEWALT Sliding Compound Miter Saw, 12-Inch (DWS779)

The DEWALT Sliding Compound Miter Saw, 12-Inch (DWS779) is a powerful tool that stands out with its strong motor power and precise cutting capabilities. The 12-inch stainless steel blade, combined with a 15-amp motor that reaches speeds of 3800 RPM, makes it suitable for cutting through metal with ease. The saw features a stainless steel miter detent plate with 10 positive stops, ensuring accuracy in your cuts. The tall sliding fences provide robust support, allowing for effective vertical cuts up to 6-3/4 inches.

Most important from

8784 reviews

Evolution S355MCS 14" Mitering Chop Saw | Heavy Duty Metal Cutting Saw | 15A/1450 RPM | TCT Blade | Sliding Head & Locking Pin | Cast Iron Clamps | Mitering Base | Knurled Fence | Quick Clamp

The Evolution S355MCS 14" Mitering Chop Saw is designed for heavy-duty metal cutting. It features a 14-inch stainless steel blade, making it highly durable and suitable for cutting various metals. The powerful 15A motor delivers 1450 rpm, providing ample power to handle tough jobs effectively.

Most important from

167 reviews

Top 10 Best Miter Saws For Metal Cutting 2025 in the United States

Winner

9.9 score

Metabo HPT 10-Inch Compound Miter Saw, 15-Amp Power Saw with Large 10-Inch Table, Precision Miter Angles, Single Bevel 0-45°, 24T TCT Blade, Positive Stops, Lightweight Design, C10FCGS

Metabo HPT 10-Inch Compound Miter Saw, 15-Amp Power Saw with Large 10-Inch Table, Precision Miter Angles, Single Bevel 0-45°, 24T TCT Blade, Positive Stops, Lightweight Design, C10FCGS

Chosen by 1366 this week

DEWALT Sliding Compound Miter Saw, 12-Inch (DWS779)

DEWALT Sliding Compound Miter Saw, 12-Inch (DWS779)

Evolution S355MCS 14" Mitering Chop Saw | Heavy Duty Metal Cutting Saw | 15A/1450 RPM | TCT Blade | Sliding Head & Locking Pin | Cast Iron Clamps | Mitering Base | Knurled Fence | Quick Clamp

Evolution S355MCS 14" Mitering Chop Saw | Heavy Duty Metal Cutting Saw | 15A/1450 RPM | TCT Blade | Sliding Head & Locking Pin | Cast Iron Clamps | Mitering Base | Knurled Fence | Quick Clamp

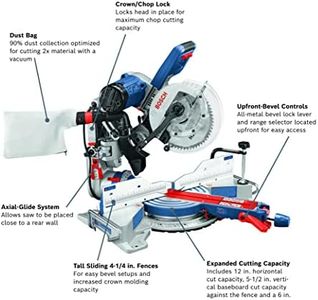

BOSCH GCM12SD 15 Amp 12 Inch Corded Dual-Bevel Sliding Glide Miter Saw with 60 Tooth Saw Blade

BOSCH GCM12SD 15 Amp 12 Inch Corded Dual-Bevel Sliding Glide Miter Saw with 60 Tooth Saw Blade

BOSCH CM10GD Compact Miter Saw - 15 Amp Corded 10 Inch Dual-Bevel Sliding Glide Miter Saw with 60-Tooth Carbide Saw Blade

BOSCH CM10GD Compact Miter Saw - 15 Amp Corded 10 Inch Dual-Bevel Sliding Glide Miter Saw with 60-Tooth Carbide Saw Blade

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.