10 Best Laser Engravers And Cutters 2025 in the United States

Winner

xTool F1 Ultra 20W Fiber & Diode Dual Laser Engraver, 10000mm/s Ultra Fast Laser Engraver and Cutter Machine for Jewelry, Metal, Wood, 16MP Smart Camera, Auto Streamline, 3D Engraving Machine

The xTool F1 Ultra 20W Fiber & Diode Dual Laser Engraver stands out with its dual laser system, featuring both fiber and diode lasers with 20W power each. This allows it to handle a wide range of materials, from metals like gold and stainless steel to wood, acrylic, and even fabric, making it highly versatile. Its ultra-fast engraving speed of up to 10,000mm/s and the ability to perform 3D embossing and deep engraving add to its appeal for creating intricate designs and high-value items.

Most important from

164 reviews

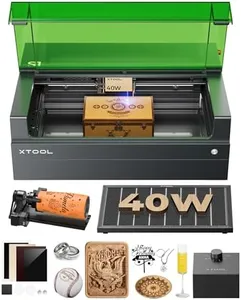

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

The xTool S1 40W Laser Cutter and Engraver offers impressive power and productivity, making it suitable for handling large projects. The 40W laser can easily cut through thick materials like 18mm cherry wood, and its speed of up to 600mm/s ensures efficient processing on its spacious 23.93" x 15.16" work area. This makes the machine ideal for tasks ranging from big signs to multiple smaller items like dog tags simultaneously.

Most important from

157 reviews

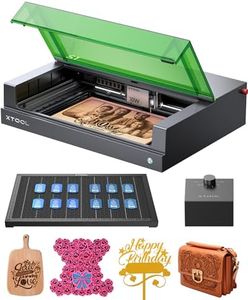

xTool S1 40W Laser Cutter and Engraver Machine, with Auto Conveyor Feeder, 118'' Long Crafts, 600mm/s Speed, Laser Engraver for Tumblers Wood and Metal, Acrylic, etc. - Deluxe Bundle

The xTool S1 40W Laser Cutter and Engraver is a robust option for those seeking a powerful machine for diverse projects. With a substantial 40W laser, it efficiently cuts through materials like 18mm cherry wood, making it a compelling choice for woodworking enthusiasts and those working with metals and acrylics. The large work area of 23.93" x 15.16" accommodates significant projects and supports high-speed engraving up to 600mm/s, ideal for batch processing items like dog tags.

Most important from

37 reviews

Top 10 Best Laser Engravers And Cutters 2025 in the United States

Winner

9.9 score

xTool F1 Ultra 20W Fiber & Diode Dual Laser Engraver, 10000mm/s Ultra Fast Laser Engraver and Cutter Machine for Jewelry, Metal, Wood, 16MP Smart Camera, Auto Streamline, 3D Engraving Machine

xTool F1 Ultra 20W Fiber & Diode Dual Laser Engraver, 10000mm/s Ultra Fast Laser Engraver and Cutter Machine for Jewelry, Metal, Wood, 16MP Smart Camera, Auto Streamline, 3D Engraving Machine

Chosen by 1452 this week

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

xTool S1 40W Laser Cutter and Engraver Machine, with Auto Conveyor Feeder, 118'' Long Crafts, 600mm/s Speed, Laser Engraver for Tumblers Wood and Metal, Acrylic, etc. - Deluxe Bundle

xTool S1 40W Laser Cutter and Engraver Machine, with Auto Conveyor Feeder, 118'' Long Crafts, 600mm/s Speed, Laser Engraver for Tumblers Wood and Metal, Acrylic, etc. - Deluxe Bundle

LONGER RAY5 Laser Engraver 20000mW Laser Cutter 130W CNC Laser Cutter with 3.5"Touch Screen Laser Engraving Machine DIY Engraver Tool for Metal Glass Wood Leather Laser Class ii

LONGER RAY5 Laser Engraver 20000mW Laser Cutter 130W CNC Laser Cutter with 3.5"Touch Screen Laser Engraving Machine DIY Engraver Tool for Metal Glass Wood Leather Laser Class ii

xTool S1 20W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

xTool S1 20W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

CREALITY FALCON2 22W Laser Engraver Machine with Air Assist and Rotary Roller, 220W High Accuracy Laser Engraver and Cutter Machine for Cylindrical Objects, 25000mm/min Faster Engraving

CREALITY FALCON2 22W Laser Engraver Machine with Air Assist and Rotary Roller, 220W High Accuracy Laser Engraver and Cutter Machine for Cylindrical Objects, 25000mm/min Faster Engraving

WECREAT Vision 40W Laser Engraver and Cutter Machine with Automatic Conveyor Feeder, Fume Extractor, 4-in-1 Rotary, Air Assist, Laser Bed for DIY Engraving and Cutting Acrylic Wood Metal Leather

WECREAT Vision 40W Laser Engraver and Cutter Machine with Automatic Conveyor Feeder, Fume Extractor, 4-in-1 Rotary, Air Assist, Laser Bed for DIY Engraving and Cutting Acrylic Wood Metal Leather

WECREAT Vision 20W Laser Engraver, Auto-Lifting for 5.5" Material, Smart Camera for Easiest Positioning, 600mm/s Speed, Laser Engraving Machine for Tumblers Metal Wood Acrylic DIY Craft Gifts Making

WECREAT Vision 20W Laser Engraver, Auto-Lifting for 5.5" Material, Smart Camera for Easiest Positioning, 600mm/s Speed, Laser Engraving Machine for Tumblers Metal Wood Acrylic DIY Craft Gifts Making

xTool S1 Laser Engraver and Cutter Machine with Air Assist & Honeycomb, 23.93" x 15.16" Bed Size, Beginner-friendly, Class 1 Safety Laser Engravering Machine for Wood and Metal, Acrylic - Basic Bundle

xTool S1 Laser Engraver and Cutter Machine with Air Assist & Honeycomb, 23.93" x 15.16" Bed Size, Beginner-friendly, Class 1 Safety Laser Engravering Machine for Wood and Metal, Acrylic - Basic Bundle

8.6 score

WECREAT Vista 10W Laser Engraving Machine with 9-in 1 Rotary, Smart HD Camera, Compact Diode Desktop Laser Engraver for Beginners DIY Hobbyist Wood Leather Glass Metal Jewelry Gifts Making

WECREAT Vista 10W Laser Engraving Machine with 9-in 1 Rotary, Smart HD Camera, Compact Diode Desktop Laser Engraver for Beginners DIY Hobbyist Wood Leather Glass Metal Jewelry Gifts Making

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.