10 Best Insulation Cutting Knives 2025 in the United States

Winner

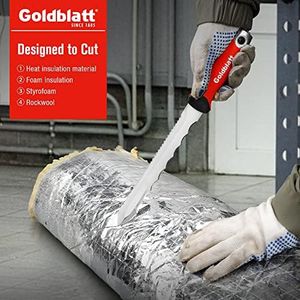

Goldblatt Insulation Knife, 8 Inch Stainless Steel Blade - Serrated Sharp Double Side Utility Knife Tool for Cutting Heat Material, Styrofoam - Rockwool Sod Cutter Lawn Repair Garden Knife

The Goldblatt Insulation Knife features an 8-inch stainless steel blade, known for its durability and rust resistance. The blade has a double-sided wavy serration design, making it versatile for cutting various materials such as heat insulation, styrofoam, and rockwool, as well as gardening tasks like sawing trees and mowing the lawn. This double-sided blade design enhances cutting efficiency and smoothness, catering to different cutting needs with its varying serration densities.

Most important from

263 reviews

Malco DK6S Double-Sided Smooth and Serrated Duct Knife

The Malco DK6S Double-Sided Smooth and Serrated Duct Knife is a versatile tool designed for both professional and DIY insulation cutting tasks. It features a 6-inch alloy steel blade, which is both durable and resharpenable, ensuring long-term use. The knife boasts a double-edged blade—one side smooth and the other serrated—offering flexibility in cutting different types of materials.

Most important from

1105 reviews

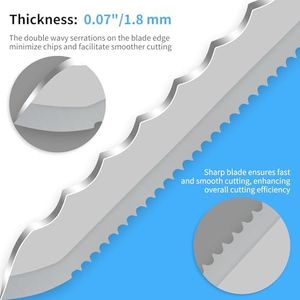

MINOVA Insulation Knife with Sheath Stainless Steel Blade 11” Double Sided Insulation Cutter for Cutting Mineral Wool Insulation Sod Cutter Garden Knife for Lawn Repair

The MINOVA Insulation Knife with Sheath is a versatile tool designed for cutting various types of insulation, including mineral wool, glass wool, and rockwool. The double-sided blade, made of durable stainless steel, is 11 inches long and features different serration densities for efficient cutting. This blade design minimizes chipping and ensures smooth cuts, which is essential when dealing with materials like insulation.

Most important from

202 reviews

Top 10 Best Insulation Cutting Knives 2025 in the United States

Winner

9.9 score

Goldblatt Insulation Knife, 8 Inch Stainless Steel Blade - Serrated Sharp Double Side Utility Knife Tool for Cutting Heat Material, Styrofoam - Rockwool Sod Cutter Lawn Repair Garden Knife

Goldblatt Insulation Knife, 8 Inch Stainless Steel Blade - Serrated Sharp Double Side Utility Knife Tool for Cutting Heat Material, Styrofoam - Rockwool Sod Cutter Lawn Repair Garden Knife

Chosen by 1150 this week

Malco DK6S Double-Sided Smooth and Serrated Duct Knife

Malco DK6S Double-Sided Smooth and Serrated Duct Knife

MINOVA Insulation Knife with Sheath Stainless Steel Blade 11” Double Sided Insulation Cutter for Cutting Mineral Wool Insulation Sod Cutter Garden Knife for Lawn Repair

MINOVA Insulation Knife with Sheath Stainless Steel Blade 11” Double Sided Insulation Cutter for Cutting Mineral Wool Insulation Sod Cutter Garden Knife for Lawn Repair

Klein Tools 31733 Insulation Knife, Cuts Foam and Fiberglass with Serrated Stainless Steel Folding Blade and Lockback Mechanism

Klein Tools 31733 Insulation Knife, Cuts Foam and Fiberglass with Serrated Stainless Steel Folding Blade and Lockback Mechanism

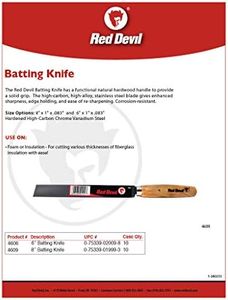

Red Devil 4609 Batting Knife, 8", Brown,8 Inch

Red Devil 4609 Batting Knife, 8", Brown,8 Inch

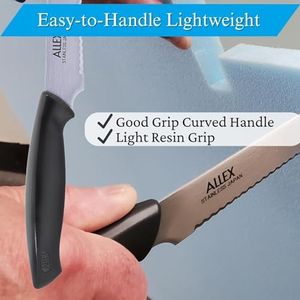

ALLEX Insulation Knife with Sheath Japanese Stainless Steel 8" Long Cut, Insulation & Styrofoam Cutter with Blade Case, Serrated Sharp Duct Knife Tool, Made in JAPAN

ALLEX Insulation Knife with Sheath Japanese Stainless Steel 8" Long Cut, Insulation & Styrofoam Cutter with Blade Case, Serrated Sharp Duct Knife Tool, Made in JAPAN

ALLEX Large Insulation Knife Extra Long Cut 11" Japanese Stainless Steel Blade, Duct Knife Tool with Sheath for Insulation, Styrofoam, Polyurethane Foam, Made in JAPAN

ALLEX Large Insulation Knife Extra Long Cut 11" Japanese Stainless Steel Blade, Duct Knife Tool with Sheath for Insulation, Styrofoam, Polyurethane Foam, Made in JAPAN

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.