10 Best Heavy Duty Concrete Crack Fillers 2025 in the United States

Winner

Sikaflex Self Leveling Sealant, Gray, polyurethane with an accelerated curing capacity for sealing horizontal expansion joints in concrete, 29 fl. oz Cartridge

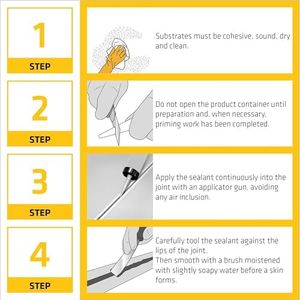

Sikaflex Self Leveling Sealant stands out for its easy application and self-leveling properties, making it user-friendly as no tooling is required. Its accelerated curing capacity allows it to become water immersible and waterproof after curing, which is beneficial in various weather conditions. The sealant offers excellent adhesion on concrete and cementitious slabs, ensuring robust bonding and long-lasting results.

Most important from

5232 reviews

Top 10 Best Heavy Duty Concrete Crack Fillers 2025 in the United States

Winner

9.8 score

Sikaflex Self Leveling Sealant, Gray, polyurethane with an accelerated curing capacity for sealing horizontal expansion joints in concrete, 29 fl. oz Cartridge

Sikaflex Self Leveling Sealant, Gray, polyurethane with an accelerated curing capacity for sealing horizontal expansion joints in concrete, 29 fl. oz Cartridge

Chosen by 1493 this week

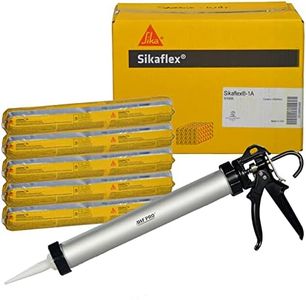

Sikaflex 1C SL 10 oz Limestone - Concrete Expansion Joint Filler, Self Leveling, Polyurethane Sealant. Pack of 12. 10 oz Applicator Gun Included

Sikaflex 1C SL 10 oz Limestone - Concrete Expansion Joint Filler, Self Leveling, Polyurethane Sealant. Pack of 12. 10 oz Applicator Gun Included

7.6 score

AWF PRO Sikaflex 1a Kit - One Component, Flexible, Non Sag, Polyurethane Concrete and Masonry Sealant for Vertical and Horizontal Surfaces, Sikaflex 1a 20 oz Sausage White (5), Caulking Gun

AWF PRO Sikaflex 1a Kit - One Component, Flexible, Non Sag, Polyurethane Concrete and Masonry Sealant for Vertical and Horizontal Surfaces, Sikaflex 1a 20 oz Sausage White (5), Caulking Gun

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.