10 Best Epoxy Concrete Crack Fillers 2025 in the United States

Winner

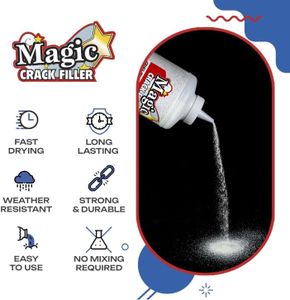

Magic Crack Filler 2LB Concrete Slab Gray, for Filling in Concrete Cracks on Driveways, Walkways and Patios. Installs Easily Dry Granular No Mess and DIY (Gray, 1)

Magic Crack Filler is a solid choice for anyone needing to repair concrete cracks on driveways, walkways, and patios. One of its main strengths is its granulated formulation, which allows for easy application on various crack sizes, from fine hairline cracks to larger damages. This versatility makes it suitable for different repair needs, whether you're a homeowner or someone managing property maintenance. The no-mess formula is another highlight; simply dampen the area and apply the powder without the hassle of mixing tools, which makes it perfect for DIY enthusiasts. It also claims to enhance the appearance of the property by blending in seamlessly with the concrete surface once applied.

Most important from

612 reviews

DAP 7079860500 Concrete Crack Filler, Gray

The DAP 7079860500 Concrete Crack Filler is designed for repairing horizontal cracks in concrete and masonry materials up to half an inch wide and deep. It comes as a water-activated dry powder, which simplifies the application—just prep the crack, fill it, and mist with water, avoiding the need for mixing or shaking. This makes it user-friendly for DIY projects or light repairs.

Most important from

297 reviews

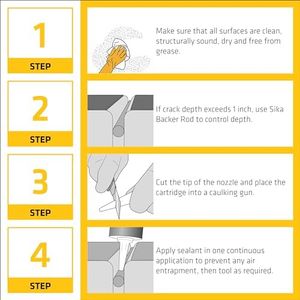

SIKA Sikaflex Self-Leveling Sealant, Gray Polyurethane, Fast Curing, for Concrete Expansion Joints, Waterproof, Paintable, Fills Cracks up to 1.5 in., 10.1 fl. oz Cartridge

The Sikaflex Self Leveling Sealant is a polyurethane-based product designed for sealing horizontal expansion joints in concrete. Its main advantage is the self-leveling property, which eliminates the need for tooling and makes application easier even for those with little experience. It can bridge gaps up to 1.5 inches wide, providing flexibility and durability.

Most important from

5251 reviews

Top 10 Best Epoxy Concrete Crack Fillers 2025 in the United States

Winner

10.0 score

Magic Crack Filler 2LB Concrete Slab Gray, for Filling in Concrete Cracks on Driveways, Walkways and Patios. Installs Easily Dry Granular No Mess and DIY (Gray, 1)

Magic Crack Filler 2LB Concrete Slab Gray, for Filling in Concrete Cracks on Driveways, Walkways and Patios. Installs Easily Dry Granular No Mess and DIY (Gray, 1)

Chosen by 1282 this week

DAP 7079860500 Concrete Crack Filler, Gray

DAP 7079860500 Concrete Crack Filler, Gray

SIKA Sikaflex Self-Leveling Sealant, Gray Polyurethane, Fast Curing, for Concrete Expansion Joints, Waterproof, Paintable, Fills Cracks up to 1.5 in., 10.1 fl. oz Cartridge

SIKA Sikaflex Self-Leveling Sealant, Gray Polyurethane, Fast Curing, for Concrete Expansion Joints, Waterproof, Paintable, Fills Cracks up to 1.5 in., 10.1 fl. oz Cartridge

Sika - Sikacryl - Gray - Ready-Mix Concrete Patch - for Repairing spalls and Cracks in Concrete and Masonry - Textured - 1 qt

Sika - Sikacryl - Gray - Ready-Mix Concrete Patch - for Repairing spalls and Cracks in Concrete and Masonry - Textured - 1 qt

DAP Concrete and Mortar Filler and Sealant, Gray, 10.1 Oz (7079818096)

DAP Concrete and Mortar Filler and Sealant, Gray, 10.1 Oz (7079818096)

RadonSeal Complete DIY Foundation Crack Repair Kit - 10 Ft - Low-Viscosity Urethane Injection Sealant for Crawl Spaces & Concrete Basement Walls, Stops Water Leaks & Radon Gas, Drill-Free Filler

RadonSeal Complete DIY Foundation Crack Repair Kit - 10 Ft - Low-Viscosity Urethane Injection Sealant for Crawl Spaces & Concrete Basement Walls, Stops Water Leaks & Radon Gas, Drill-Free Filler

DAP 37584 Liquid Cement Crack Filler, 1 quart, Gray

DAP 37584 Liquid Cement Crack Filler, 1 quart, Gray

Sikaflex Crack Flex Sealant, Gray, High performance, textured polyurethane sealant, self-leveling, sealant for sealing horizontal cracks, 10,1 fl. Oz

Sikaflex Crack Flex Sealant, Gray, High performance, textured polyurethane sealant, self-leveling, sealant for sealing horizontal cracks, 10,1 fl. Oz

Red Devil 0645 Concrete Repair Patch, Cement Crack Filler, 5.5 Oz Squeeze Tube, Pre-Mixed, Pack of 1, Gray, Made in USA

Red Devil 0645 Concrete Repair Patch, Cement Crack Filler, 5.5 Oz Squeeze Tube, Pre-Mixed, Pack of 1, Gray, Made in USA

8.3 score

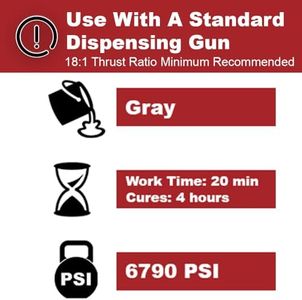

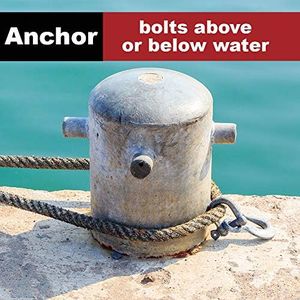

PC Products 72561 PC-Concrete Two-Part Epoxy Adhesive Paste for Anchoring and Crack Repair, 8.6 oz Cartridge, Gray

PC Products 72561 PC-Concrete Two-Part Epoxy Adhesive Paste for Anchoring and Crack Repair, 8.6 oz Cartridge, Gray

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.