10 Best American Made Drill Presses 2025 in the United States

Winner

ZELCAN Magnetic Drill Press with 11 Drill Bits, 1550W Mag Drill Press with 2" Dia. 3125 lbf/13900N Mag Force, 650 rpm Power Magnetic Drill with Stepless Speed & Reversible Direction for Metal Surface

The ZELCAN Magnetic Drill Press offers impressive features with its 1550W motor, capable of 650 RPM, and the ability to handle holes up to 2 inches in depth and diameter. This makes it suitable for demanding tasks like industrial steel fabrication and bridge building. The drill's 13900N magnetic force ensures stability and precision during operation, which is crucial for accurate drilling.

Most important from

102 reviews

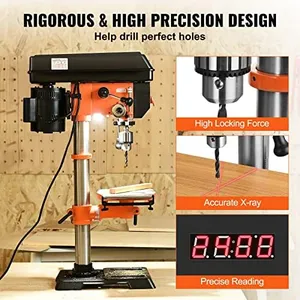

VEVOR 12 in Benchtop Drill Press, 5 Amp 120V, Variable Speed Cast Iron Bench Drill Press, 12 in Swing Distance 0-45° Tiltling Worktable with Laser Work Light, Tabletop Drilling Machine for Wood Metal

The VEVOR 12 in Benchtop Drill Press is a versatile tool designed for both hobbyists and professional users seeking a reliable solution for woodworking and metalworking tasks. It features a 5 Amp motor, providing ample power to handle various materials. The drill press is equipped with a 12-inch swing and a variable speed range between 580 and 3200 RPM, allowing users to adjust for precision and control depending on the material and task at hand. The addition of a digital LED screen aids in accurately setting the desired speed.

Most important from

153 reviews

Top 10 Best American Made Drill Presses 2025 in the United States

Winner

9.9 score

ZELCAN Magnetic Drill Press with 11 Drill Bits, 1550W Mag Drill Press with 2" Dia. 3125 lbf/13900N Mag Force, 650 rpm Power Magnetic Drill with Stepless Speed & Reversible Direction for Metal Surface

ZELCAN Magnetic Drill Press with 11 Drill Bits, 1550W Mag Drill Press with 2" Dia. 3125 lbf/13900N Mag Force, 650 rpm Power Magnetic Drill with Stepless Speed & Reversible Direction for Metal Surface

Chosen by 1429 this week

VEVOR 12 in Benchtop Drill Press, 5 Amp 120V, Variable Speed Cast Iron Bench Drill Press, 12 in Swing Distance 0-45° Tiltling Worktable with Laser Work Light, Tabletop Drilling Machine for Wood Metal

VEVOR 12 in Benchtop Drill Press, 5 Amp 120V, Variable Speed Cast Iron Bench Drill Press, 12 in Swing Distance 0-45° Tiltling Worktable with Laser Work Light, Tabletop Drilling Machine for Wood Metal

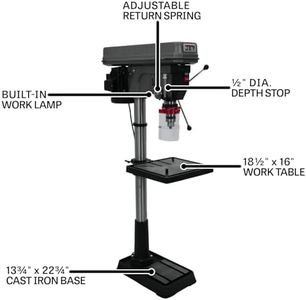

JET 20-Inch Floor Drill Press, 12 Speed, 1-1/2 HP, 115/230V 1Ph (Model JDP-20MF)

JET 20-Inch Floor Drill Press, 12 Speed, 1-1/2 HP, 115/230V 1Ph (Model JDP-20MF)

SKIL 6.2 Amp 10 In. 5-Speed Benchtop Drill Press with Laser Alignment & Work Light - DP9505-00

SKIL 6.2 Amp 10 In. 5-Speed Benchtop Drill Press with Laser Alignment & Work Light - DP9505-00

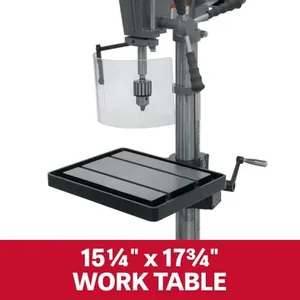

JET 15-Inch Benchtop Drill Press, 16 Speed, 3/4 HP, 115/230V 1Ph (Model J-2530)

JET 15-Inch Benchtop Drill Press, 16 Speed, 3/4 HP, 115/230V 1Ph (Model J-2530)

JET 15-Inch Floor Drill Press, Variable Speed, 1 HP, 115/220V 1Ph (Model J-A5816)

JET 15-Inch Floor Drill Press, Variable Speed, 1 HP, 115/220V 1Ph (Model J-A5816)

8.3 score

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.