10 Best Aluminum Bar Clamps 2025 in the United States

Winner

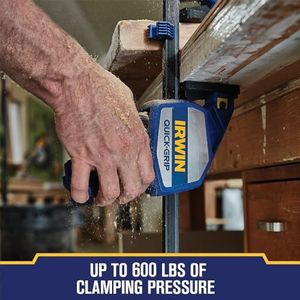

IRWINQUICK-GRIPOne-Handed Mini Bar Clamp 2 Pack, 6", 1964743

The IRWIN QUICK-GRIP One-Handed Mini Bar Clamp 2 Pack, 6", is a versatile tool designed for convenience and efficiency, especially when working with smaller workpieces or in confined areas. One of its standout features is the non-marring pads that provide a firm grip while protecting your workpiece from damage, making it suitable for delicate tasks. The one-handed Quick-Release trigger adds to its ease of use, allowing for quick adjustments and releases without needing both hands, which can be a significant advantage in many situations.

Most important from

22678 reviews

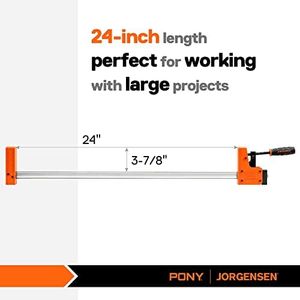

JORGENSEN 24-inch Bar Clamps, 90°Cabinet Master Parallel Jaw Bar Clamp Set, 2-pack

The JORGENSEN 24-inch Bar Clamps from HANGZHOU GREATSTAR INDUSTRIAL CO.,LTD offer a solid clamping solution for woodworking projects. With a maximum clamping capacity of 24 inches, these clamps are versatile enough for various tasks like panel glue-ups, boxes, cabinets, frames, and raised panel doors. They boast a strong clamping force of up to 1500 lbs., thanks to the heavy-duty steel jaws and high-carbon steel bar. This makes them highly effective for holding workpieces firmly in place.

Most important from

1035 reviews

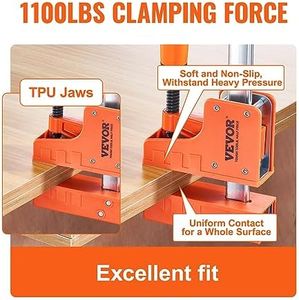

VEVOR Bar Clamps for Woodworking, 2-Pack 50" Parallel Clamp Set, F Clamp with 1100 lbs Load Limit, Even Pressure, High-strength Plastic and Carbon Steel, Wood clamps for Woodworking Metal Working

The VEVOR Bar Clamps for Woodworking come as a 2-pack with a 50-inch jaw opening, making them suitable for standard-sized wood projects. They boast a strong load limit of 1100 lbs, which allows them to securely handle various woodworking and metalworking tasks. The bars are made from 45# carbon structural steel, providing durability and resistance to cracking, while the handles are crafted from high-strength plastic, offering better durability than ABS.

Top 10 Best Aluminum Bar Clamps 2025 in the United States

Winner

9.9 score

IRWINQUICK-GRIPOne-Handed Mini Bar Clamp 2 Pack, 6", 1964743

IRWINQUICK-GRIPOne-Handed Mini Bar Clamp 2 Pack, 6", 1964743

Chosen by 1332 this week

JORGENSEN 24-inch Bar Clamps, 90°Cabinet Master Parallel Jaw Bar Clamp Set, 2-pack

JORGENSEN 24-inch Bar Clamps, 90°Cabinet Master Parallel Jaw Bar Clamp Set, 2-pack

VEVOR Bar Clamps for Woodworking, 2-Pack 50" Parallel Clamp Set, F Clamp with 1100 lbs Load Limit, Even Pressure, High-strength Plastic and Carbon Steel, Wood clamps for Woodworking Metal Working

VEVOR Bar Clamps for Woodworking, 2-Pack 50" Parallel Clamp Set, F Clamp with 1100 lbs Load Limit, Even Pressure, High-strength Plastic and Carbon Steel, Wood clamps for Woodworking Metal Working

Jorgensen 12-inch Bar Clamp Set, Bar Clamp for Woodworking, Quick Release Gear Clamp with 600 lbs Load Limit - 2 Pack

Jorgensen 12-inch Bar Clamp Set, Bar Clamp for Woodworking, Quick Release Gear Clamp with 600 lbs Load Limit - 2 Pack

Jorgensen 24" One Hand Clamp/Spreader - 2-pack, Medium Duty, E-Z Hold Bar Clamps Set

Jorgensen 24" One Hand Clamp/Spreader - 2-pack, Medium Duty, E-Z Hold Bar Clamps Set

Dubuque Clamp Works UC948 48" Adjustable Bar Clamp for Woodworking - 4-PACK

Dubuque Clamp Works UC948 48" Adjustable Bar Clamp for Woodworking - 4-PACK

Jorgensen 2-pack Medium Duty Steel Bar Clamp Set with 600 lbs Load limit, 24-inch

Jorgensen 2-pack Medium Duty Steel Bar Clamp Set with 600 lbs Load limit, 24-inch

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.